Passionate about designing the most accurate alignment systems possible, Martin Hamar founded the company that bears his name and set up shop—in the family home.

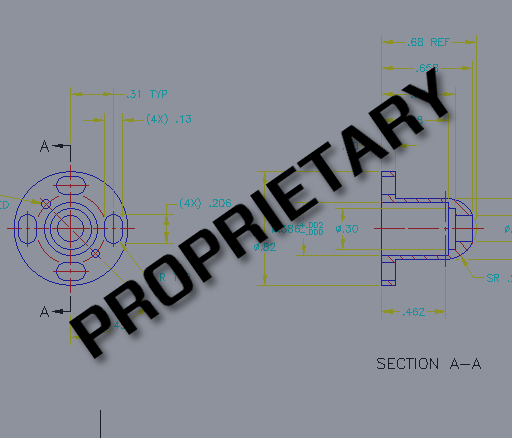

Making one change per day to his design for 1 1/2 years, Hamar painstakingly developed the famous “xxxx mount” (sorry it’s secret) to provide adequate stability for the laser source.

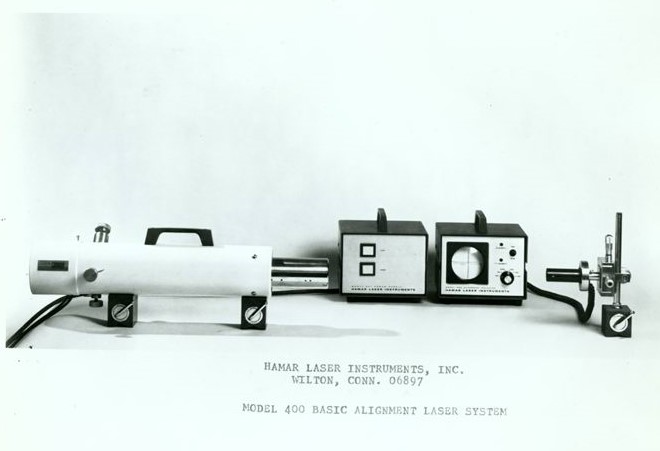

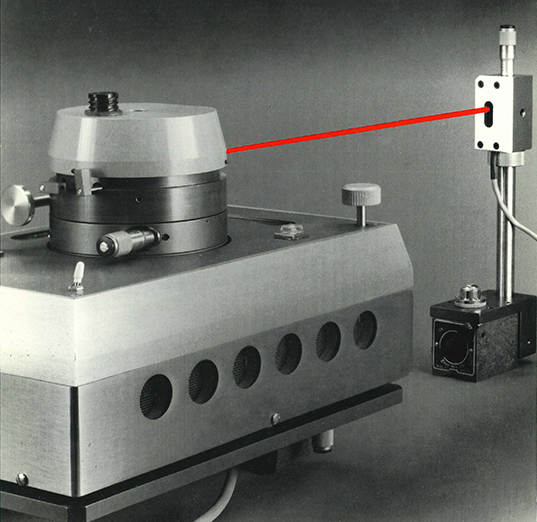

Hamar meticulously designed his first alignment system, the Model L-400, a straight-line alignment laser, and made his first sale to a local company, Farrel Corporation, that remains a customer today!

After hiring a number of employees, Hamar moved into a commercial facility in Wilton, Connecticut. “My wife got tired of making us lunch!” our founder quipped.

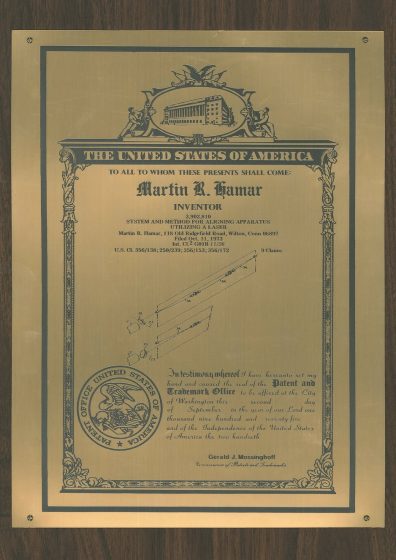

When you are innovating, you want to protect your investment, so we filed our first patent, which was received on October 11, 1973. This was the first of many patents to come – 25 in fact!

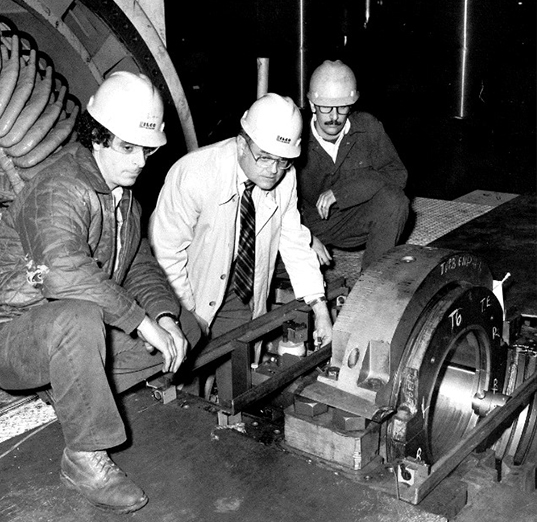

Our first bore alignment system, we developed a custom alignment system for Westinghouse’s steam turbines that produced much more accurate and repeatable alignment data in 50% less time than their conventional methods.

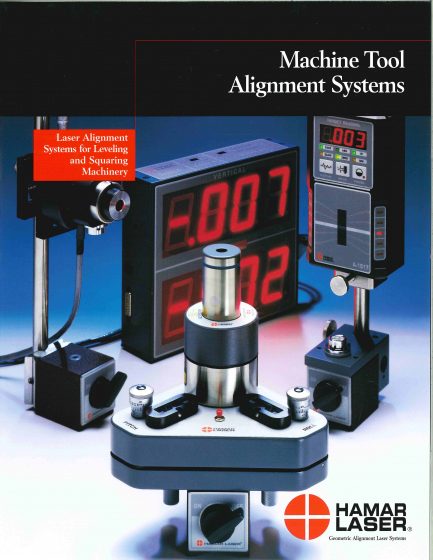

The Model L-711 laser alignment system was the first such system to feature a pentaprism that created a manually sweeping precision laser plane. The ground-breaking alignment device was accurate to less than 0.5 arc-sec (0.0025 mm/m)!

Modifications to the Model L-711 laser alignment system made it the first such system to feature an “auto-scanning” or automatically sweeping precision laser plane. This also required the development of a target that can capture a laser beam traveling at 300 RPM – no easy task in the 1970’s!

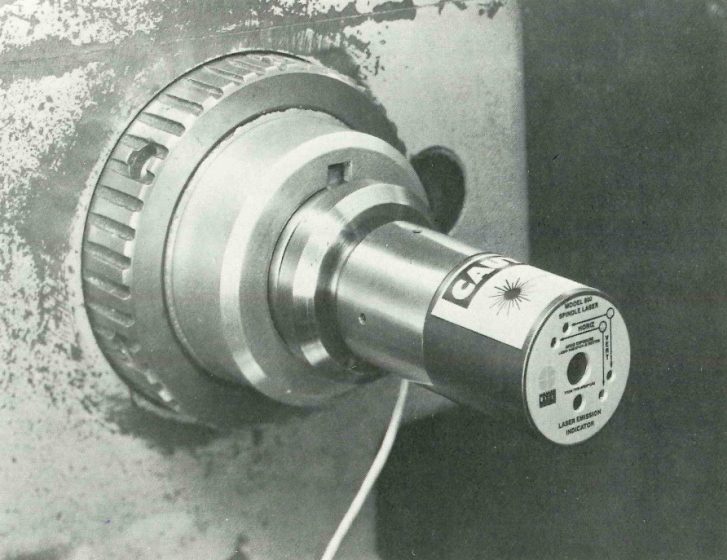

Hamar Laser’s innovative L-800 spindle laser alignment system was the first such system on the market to feature an advanced invisible (infra-red) diode-based laser.

Using the latest development in laser diodes, we were finally able to see the laser beam without a viewer! We also added a replaceable battery to get rid of a wire. The L-700 has been a workhorse ever since!

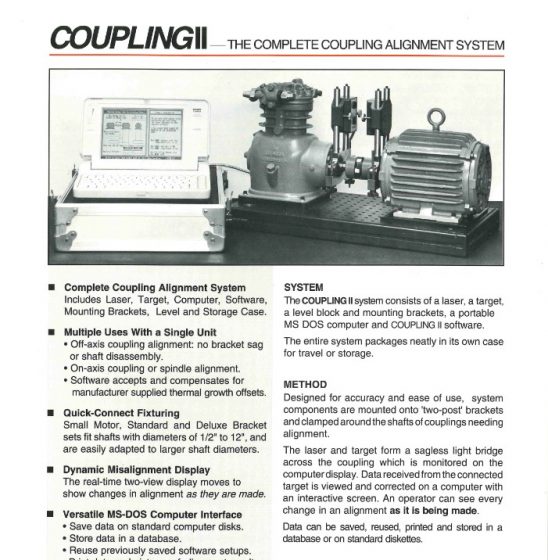

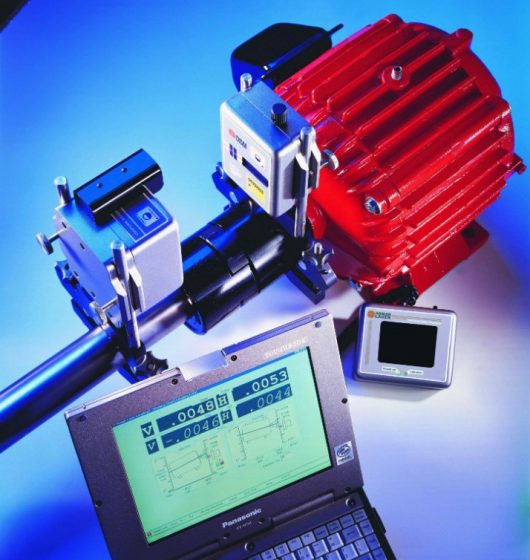

The S-640 Coupling II laser alignment system featured the first advanced visible (diode-based) shaft alignment laser on the market and was the first 4-axis system, something our competitors took many years to copy!

Hamar Laser’s flagship Triple-Scan® alignment system debuted as the Model L-723. Its successor, the Model L-743, is still the only such system on the market featuring 3 automatically rotating laser planes – a must have for quickly aligning large machining centers.

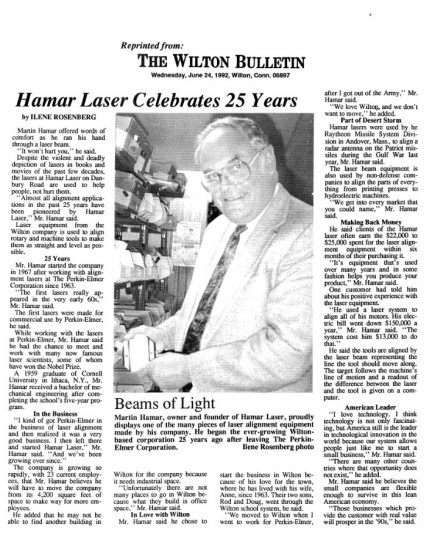

By 1992, Hamar Laser had become the pioneer developer of systems for numerous alignment applications in many industries around the world and requiring an even bigger building.

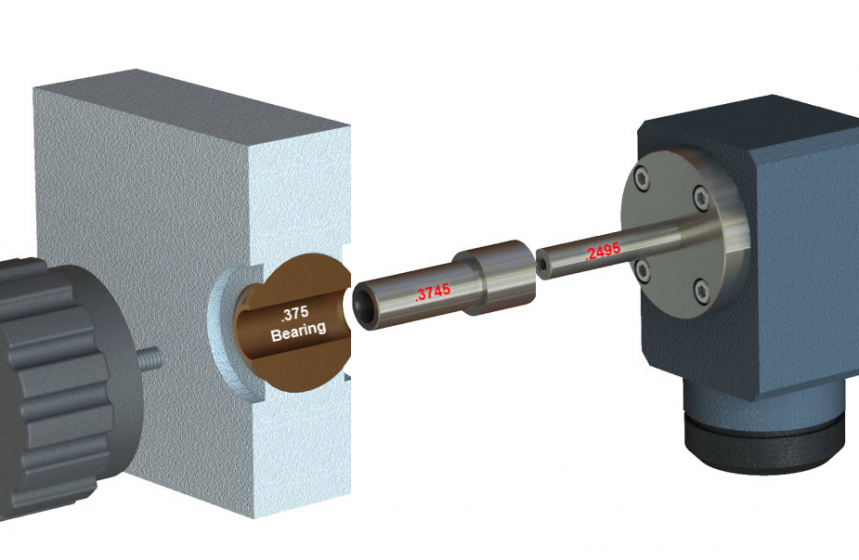

This ingenious system was built around a patented, 2-Axis Self-Centering Target that automatically finds the center of the bore with no moving parts. It takes 5 seconds to get a bore measurement.

Another of many industry “firsts”: The Model L-720 was the first laser alignment system on the market to feature a simultaneous scan plane and square plumb beam.

On its 30th anniversary, Hamar Laser moved its growing workforce to the present state-of-the-art facility in Danbury, a location ideally suited to manufacturing operations.

GM asked us to make an accurate pulley alignment system for their OD grinders. So we did and it made the cover of NED Magazine! The only problem was it was too accurate and too expensive for most standard pulley applications but boy could it align pulleys…

Forerunner of today’s X-SERIES™ X-880, the S-650 featured our patented Dual-Beam™ technology allowing measurement of offset and angle simultaneously with just one sensor. It was the first wireless shaft alignment system on the market.

We finally got rid of the wires for our L-720 Series scanning lasers when we introduced our A-1519/A-1520 Type I wireless infra-red targets! Our salesmen and customers were extremely happy!

Utilizing our “virtual” target optical design, making the target insensitive to angle, we came out with the only target in the world to work in small spherical bearings in commercial aircraft applications. The T-271 can easily align bearings down to .25 (6 mm). Our biggest ROI system to date! The old method was 2 shifts, 4 technicians and lots of frustration. This was reduced to 2 technicians in 2 hours. When you’re making 2 planes per day, that adds up quick!

Design enhancements strengthened the L-743’s position as the most versatile machine tool laser alignment system on the market, featuring the flattest laser plane in the World.

Infra-red (IR) communication had its limitations, so we updated our A-1519/A-1520 Targets to use the predecessor to the XBE radios we now use. This meant up to 99 targets could be used with 1 radio base station. This came in handy when Boeing asked us if we could supply 14 targets for a wing assembly application!

After 19 years of making the World’s most accurate and easy-to-use shaft alignment systems, Hamar Laser introduced its redesigned line of shaft products, rebranding them under the not-so-secret Stealth Series™ name and logo.

Based on Hamar Laser’s innovative bore alignment technology, the L-708 was deigned to mount inside a bore using our patented A-514 self-centering bore adapters. This really simplified and sped up bore alignment laser setups.

Based on Hamar Laser’s innovative bore technology, this specialized variation of the L-706 and the A-516 self-centering target offered extremely accurate and fast measurement of large gun bores. It utilized roller bearings for the measuring tips, so it was much easier to insert the target deep into a 10 meter long barrel!

IHI, a Japanese heat-exchanger manufacturer, asked us to make a self-centering target for small bores down to .7 in. (17.8 mm) to measure tube sheet bores. The T-220 Small-Bore Self-Centering Target was born!

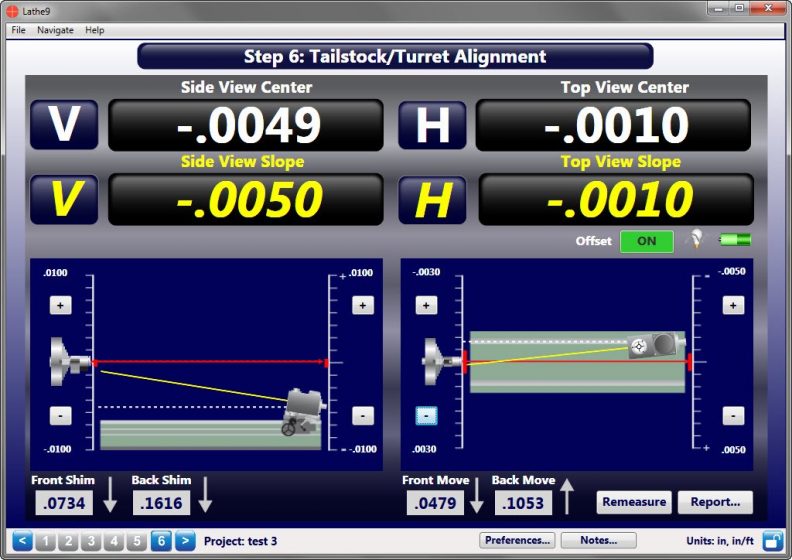

Windows-based Lathe9 was written to use with our L-700 Spindle Alignment system for aligning lathes and turning centers. It has step-by-step instructions for checking all the alignment parameters of a lathe.

Combining our A-512 Adjustable Self-Center Bore Target and adjustable bore adapters with our L-706 and other accessories created the most accurate bore alignment system on the market. .00025 in. (0.005 mm) in 10 ft. (3 m) is pretty good we think…

Beginning with just one inspired product, Hamar Laser turned 50 designing and manufacturing alignment systems that address virtually any alignment challenge and serves customers on 6 continents around the world.

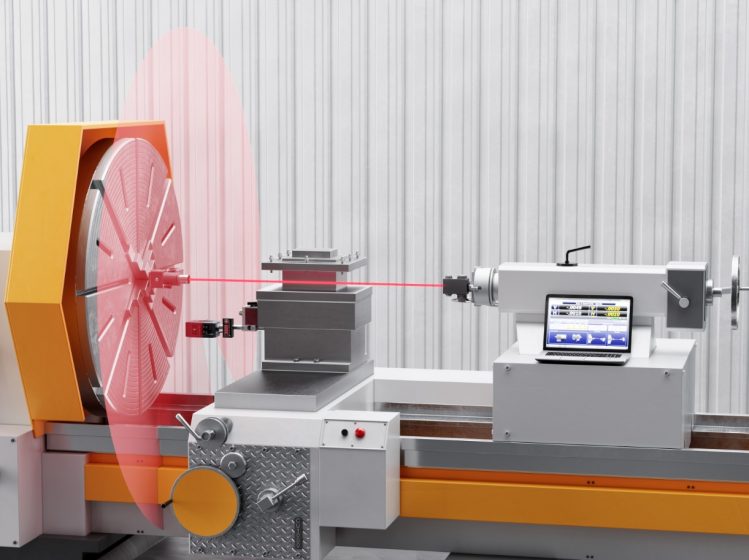

A new set of lasers for today’s modern CNC turning centers and the complicated multi-turn machine tools. Compact and able to measure complicated alignments with ease.

It took over a year to tame our old beast of a website to come out with a new site that features videos, application notes, a much easier navigation system and much more!

We finally ported over our popular Read15 PDA software to the Android platform to run on a new, rugged PDA that we now supply. Next step is for it to run on your phone!

Our journey of innovation and excellence continues: We’re planning the next 50 years now!

Accurate, economical and versatile alignment solutions are more important now than ever…

Learn more about our laser alignment solutions.

We want you to be part of our future!