L-732 Precision Dual Scan® Laser

Hamar Laser’s L-732 Precision Dual Scan® Laser Alignment System is designed for quickly and accurately aligning all types of machinery with rolls, such as roll-forming machines, film lines and printing presses, as well as several other similar applications, where the required accuracy is a lot lower than that of our L-742 Ultra-Precision Laser. The L-732 can be configured by the factory to have either 2 vertical laser planes (the typical configuration for roll alignment), or 1 horizontal and 1 vertical laser plane (for measuring flatness, straightness and squareness of surfaces and lower-accuracy machine axes). This creates a powerful tool that not only measures alignment, but also re-aligns machinery in a fraction of the time needed with conventional methods.

System Highlights

- Fast: Aligns roll-forming machinery and other roll alignment applications up to 70% faster than traditional methods.

- Easy: Multiple high-resolution wireless targets with a range of up to 100 ft provide live alignment data, so alignment errors can be fixed without changing the setup.

- Accurate: Precision laser planes have a flatness of 2 arc seconds (.00012 in/ft or 0.01 mm/m).

- Versatile: Depending on the laser plane configuration, the system is ideal for virtually all roll machinery; plus machining centers, gantries, roll forming machines and many other applications.

- Smart: Powerful Windows-based alignment software, combined with advanced wireless interfaces, makes collecting and analyzing alignment data fast and easy.

Key Features

- 2 continuously rotating laser planes with operational range of 100 ft (30.5 meters) in radius with 2 configurations:

- 2 vertical laser planes, typically used in roll alignment; and

- 1 vertical and 1 horizontal laser plane, typically used for machine-tool axis (or surface) flatness, straightness and squareness.

- Backlit levels accurate to .00018 in/ft (0.015mm/m or 3 arc secs). Upgrade to Split-Prism level vials that are accurate to .00006 in/ft (0.005 mm/m).

- Laser planes flat to .00012 in/ft (0.01 mm/m or 2 arc seconds).

- Planes are square to each other up to .00012 in/ft (0.01 mm/m or 2 arc seconds).

- Standard targets: A-1519-2.4XBE Single-Axis Wireless Targets with 1 in. (25.4 mm) Measuring Range and .00002 in. (0.0005 mm) Resolution.

- Optional high-accuracy targets: A-1520-2.4XBE Single-Axis Wireless Targets with .39 in. (10 mm) Measuring Range and .00001 in. (0.00025mm) Resolution.

- R-1358-2.4XBE PDA Readout displays data for up to 5 A-1519-2.4XBE Targets simultaneously.

- For roll alignment system configuration, factory-built benchmark fixtures and laser translation slide are included in system.

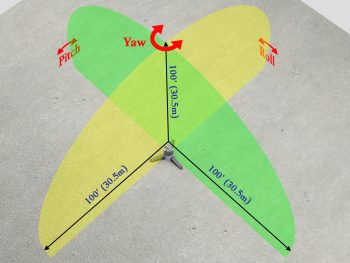

- Includes Pitch/Roll/Yaw base with coarse adjustments.

- Battery or AC powered.

- Typical setup time is 15 minutes or less.

If you do not see your application listed, please contact us to discuss your requirements. We will be more than happy to provide a solution that’s right for your unique alignment problem.

Applications

- Aircraft Interior Alignment (Storage Bins, Galleys, etc.)

- Floor Beam Alignment

- Jig/Tooling Calibration and Leveling

- Seat-Track Alignment

Fabricating Machinery

- Laser-Cutting Machines

- Routers

- Saw Mills

- Tube-Bending Machines

- Water-Jet Machines

- Woodworking Machines

Fabrication Alignment

- Agricultural Machinery Assembly

- Large Construction Machinery Assembly

- Locomotive Assembly

- Truck Bed Assembly

Leveling

- Machine Bed Leveling

- Split Joints on Steam Turbines

Machine Tools – Lower Accuracy

- Floor and Spar Mills

- Gantries

- Horizontal and Vertical Boring Mills

- Horizontal and Vertical Machining Centers

- Large-Lathe Beds

- Machine Tool Assembly and Calibration

- Roll-Forming Machines

- Vertical and Horizontal Presses

- Vertical-Turning Lathes

Plastics

- Blown-Film Lines

- Film Lines

- Injection Molding Machines

Quality Control

- Calibration of Large Fixtures

- Large-Part Flatness, Straightness and Squareness

Roll Alignment

- Aluminum Mills

- Continuous Casting Machines

- Steel Mills

- Textile Mills

Ship Building

- Gun Bearing Alignment

- LNG Tanker Hull Construction

- Section Alignment and Layout

L-732 Precision Dual Scan® Laser Alignment System

Primarily designed for roll alignment and other similar alignment applications that do not require the exacting tolerances of the L-742 Ultra-Precsion Laser, the L-732 Precision Dual Scan® Laser System offers 2 automatically rotating laser planes that can be configured by the factory to have either 2 vertical planes, or 1 horizontal and 1 vertical laser plane. Affordable, yet powerful, the L-732 not only MEASURES but it also FIXES alignment errors in a fraction of the time needed with conventional methods.

2 Arc Second Accuracy

One of the critical components of any laser system is the straightness or flatness of the laser beam or plane, as this is the reference from which the measurements are made.

The L-732’s laser planes are flat and square to 0.00012 in/ft. (0.01 mm/m or 2 arc seconds). It comes with a pitch, roll and yaw adjustment base, for setting the laser planes parallel to reference points, 2-arc-second level vials and a powerful magnet for maximum stability.

Two Configurations for Many Different Applications

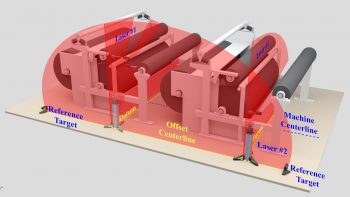

With two continuously sweeping, ultra-flat, orthogonal laser planes, the L-732 Dual Scan® Laser System is ideally suited for a whole host of alignment applications. The L-732 comes in 2 configurations. The standard L-732 has 1 horizontal laser plane and 1 vertical laser plane. It is used for measuring flatness straightness and squareness on machining centers, gantries and roll forming machines.

The L-732WW has 2 vertical laser planes and is used primarily for aligning the horizontal roll parallelism of printing presses, paper mills, films lines and other roll alignment applications.

High Resolution Wireless Targets

Another critical component of flatness or straightness measurements is the resolution laser beam detector. This determines how close the measurements can be made.

The L-732 system uses our line of wireless targets (A-1519-2.4ZB and A-1520-2.4ZB) that feature up to 0.00002 in. (0.0005 mm) resolution, large measuring ranges of up to 1 in. (25 mm) and 2.4 GHz “Zigbee” radio wireless communication with our R-1357-2.4ZB PDA Readout, which can simultaneously display up to 5 targets.

These lightweight targets are all powered by rechargeable batteries and can be used as digital height gages when used with precision inserts. And like all Hamar Laser systems, the targets provide real-time alignment data so misalignment errors can be fixed without changing the setup!

Alignment Applications

For alignments with tolerances of 0.00015 in/ft or (0.01 mm/m) or greater, the L-732 can quickly measure and correct machine geometry with minimal setup in the following applications:

- Water-jet cutting machines

- Laser-cutting machine

- Normal or blown-film lines (roll alignment)

- Rubber (roll alignment)

- Steel (roll alignment)

- Textiles (roll alignment)

- Saw Mills

- Leveling almost any surface (squares, frames, ways, flanges, circles, etc.)

- Measuring and aligning:

- The flatness of almost any vertical surface (squares, frames, ways, flanges, circles, etc.)

- The squareness of any 2 vertical surfaces

- The flatness and straightness of vertical surfaces

- The straightness of horizontally and vertically traversing axes

- The parallelism of vertical or horizontal surfaces, even if those surfaces are 100 feet (30.5 meters apart)

- Checking plumb of a vertical surface up to 100 feet (30.5 meters)

- Checking way twist and parallelism between vertical surfaces

- Measuring surfaces up to 200 feet (61 meters) long with 1 setup

Downloads

- L-732 Roll Alignment Brochure – Rev D1

- L-733 – L-743 Machining Center Alignment Brochure – Rev D1

- A-1519/A-1520-2.4ZB Type II Wireless Target Manual – Rev H

- A1519 RS485 Cable Connection Diagram – Rev B

- A-1519-1520 Data Format – Type II – Programmer’s note -1 or 2-axis targets

- L-106 Datasheet – Rev F

- R-1307B Basic Readout Datasheet -with KS – Rev F2

- R-1358-2.4XBE PDA Android Data Display – Rev A4

- S-1388 Plane5 Software Version II – Rev A

- S-1388 Plane5 Software Sample Report – Square

- S-1387 Machine Geo Software – Rev C

- Machine Geo Sample Report

- S-1405 Read15 PDA Software – Rev A

- Call Us: +1-203-730-4600

- Email: sales@hamarlaser.com

- Website: www.hamarlaser.com