L-703 Bore, Spindle & Straightness Laser Alignment Systems

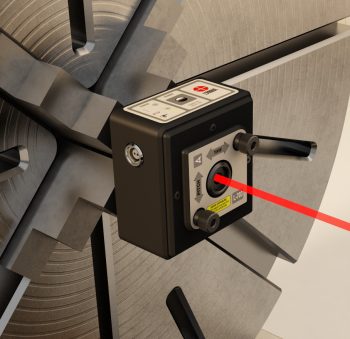

Our newest line of lasers, the L-703 Bore, Spindle & Straightness Laser Alignment Systems are small, compact, highly accurate and simple to use. They can be used on a wide variety of applications from bore alignment to spindle alignments to surface plate calibration. They feature a .500 in. (12.7 mm) mounting stud for easy insertion into spindles or into our L-112 Laser Stand for bore alignments. They also feature a newly design L-103 Laser Beam Translator for ultra-accurate laser centering to bores or spindle rotation axes. The line has 5 alignment kit packages for various applications:

- L-703B Engine Block Bore Alignment Laser

- L-703 Guideway Straightness-Measuring Laser

- L-703S Lathe & Spindle Alignment Laser

- L-703B Twin-Barrel Extruder Alignment Laser

- L-703SP Surface Plate Calibration System

System Highlights

- Fast: Do a quick alignment check in 15 minutes and get full alignment data in 25-30 minutes on most machines.

- Easy: Laser and target mount directly into the spindle and tailstock, respectively, or in laser/target stands and mounting fixtures, allowing the entire length of even the machines to be quickly and easily aligned without changing setups, replacing cumbersome and impractical alignment test bars.

- Versatile: The L-703 lasers are configured for specific applications and are combined with different targets and fixturing to meet the application need, such as bore alignment and guideway straightness applications.

- Accurate: Ultra-high resolution of up to .00001 in. (0.00025 mm) combined with software to correct mounting errors produces a very accurate alignment, less than .0001 in. (0.0025 mm) and .0001 in/ft (0.0083 mm/m) under good environmental conditions.

- Time Saving Fixturing: We have several laser and target stands for various applications, making the laser easier to set up and speeding up laser buck-ins.

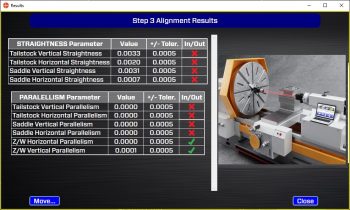

- Bore9, Lathe10 and Plane6 PC-Based Software: Large, easy-to-see alignment displays, real-time alignment data, machine graphics, and an easy-to-follow, built-in procedure to guide users through the alignment with on-screen help instructions.

Key Features

- L-703 mounts directly in the spindle collet or chuck to project its axis of rotation out to 50 ft. (15 m). A long-distance version is also available.

- Several laser mounting fixtures to rigidly hold the laser in place.

- Vertical and horizontal angular adjustment resolution of .00002 in/ft. (0.0017 mm/m)

- L-703, L-703B, and L-703S Lasers and T-1295 and T-1296 Targets all have a .500 in. (12.7 mm) mounting stud for simple fixturing to hold them in place.

- Laser beam is centered to mounting stud to <.0005 in. (0.013 mm).

- 15-minute setup time.

- For spindle application, the T-1295 5-Axis Target offset resolution is .00002 in. (0.00025 mm) and angular resolution is .00008 in/ft (0.007 mm/m).

- High-resolution T-1296 5-Axis Target has 2x higher resolution and accuracy.

- Real-time measurement data in 4 axes (V center, V angle, H center & H angle)

- Windows 7/8/10-based Bore9, Lathe10 and Plane6 PC-Based Software corrects mounting errors, records data, calculates shim values and provides an alignment report showing all the alignment parameters of lathe alignment.

- Optional L-103 Optical Laser Beam Translator can precisely position laser to rotation axis or bore center to .0001 in. (0.0025 m).

- Rechargeable Li-On battery with 11+-hour battery life for laser and targets.

- Only needs 5.6 in. (142 mm) of space between spindle and tailstock or sub-spindle.

- Combine the L-112 Laser Stand and A-510 & A-221 Self-Centering Bore Targets for many different bore alignment apps as well as guideway straightness applications.

If you do not see your application listed, please contact us to discuss your requirements. We will be more than happy to provide a solution that’s right for your unique alignment problem.

Applications

Aerospace

- Hinge-Line Spherical Bearing Bores

Bore Alignment

- Compressors

- Cylinders

- Large-bore gun barrels

- Large diesel engine blocks

Machine Tools

- CNC Lathes and Turning Centers

- Cylindrical, OD/ID Grinders

- Horizontal Boring Mill Indexing Checks for Deep-Bore Applications

- Rotary-Dial Machines

- Transfer-Line Spindle Alignments

Machine Tool Assembly

- Spindle Rotation Axis Alignment to Lathe Beds

- Straightness of Machine-Bed Guideways & Rails

- Tailstock Rotation Axis Alignment to Headstock

- Turret Alignment

Plastics

- Injection Molding Machines

- Twin-Barrel Extruders

Quality Control

- Granite Surface Plate Calibration

- Large Steel Surface Plate Calibration

L-703S Ideal for Spindle Alignment

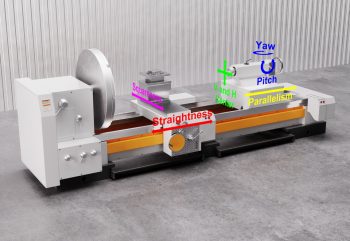

The L-703S Lathe & Turning Center Spindle laser package is ideal for measuring spindle alignment on lathes, turning centers and ID/OD grinders. Combined with our T-1295 5-Axis Wireless Target and Lathe10 software, the L-703 is a quick and very accurate tool to quickly check spindle-to-subspindle alignment, headstock spindle axis-to-guideway alignment and guideway flatness/straightness.

T-1295/T-1296 5-Axis, Wireless, Multi-Purpose Scan & Spindle Targets

The T-1295/1296 5-Axis, Wireless, Multi-Purpose Scan & Spindle Targets have up to .00001 in. (0.00025 mm) resolution and high accuracy for extremely accurate spindle alignments. Insert an angular optic and the targets measure the angle of the rotation axis relative to the laser, all in real time so realignment is fast and easy. Switch to Scan Mode and the T-1295/1296 can be used with any of our autorotating lasers. Bluetooth communication with the PC means data recording is fast and easy.

Simple Fixturing for Fast Setup

The L-703 Lasers have been designed with a .4995 in. ( 12.69 mm) mounting stud that can easily be chucked up into a spindle or fits into our L-112 Laser Stand. The laser beam is concentric to the stud OD to within .0005 in. (0.013 mm). A simple fixture with a .500 in. (12.7 mm) hole is all that is needed to hold the L-703 in place.

Wide Angular Adjustment Range

The L-703 Lasers have an angular adjustment (pitch/yaw) range of ±0.36° (± .075 in./ft or ± 6.3 mm/m) and an adjustment resolution of .00002 in/ft. (0.0016 mm/m). It can be used on applications up to 50 feet (15 m), such as compressor, engine blocks, cylinders and twin-barrel extruders.

L-703B Package for Bore Alignment

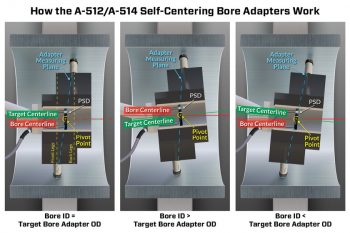

The L-703B can be packaged with our L-112 Laser Stand, L-103 Optical Beam Translator and our patented, self-centering targets to offer one of the most accurate bore alignment systems on the market. The ultra-precise L-703 Laser means accuracies down to .0002 in. (0.005 mm) in 10 feet (1 m) are no problem for the L-703 Self-Centering Bore Alignment System.

Patented, Self-Centering Target Bore Adapters

Hamar Laser has developed the world’s first self-centering targets (A-510, A-512, T-220, T-221, T-1240) and bore adapters (A-510STA/A-510LTA, A-512STA/A-512LTA, A-514A/B/C, T-221STA) that use no moving parts to self center in a bore. It takes just seconds to position the target in the barrel for an accurate measurement down to .0002 in. (0.005 mm). This eliminates the annoying 0 and 180 measurements needed for typical bore targets.

Guideway Straightness, Flatness, Pitch and Yaw

Package the L-703S with the L-112 Laser Stand, L-702MB Mag Base Fixture and T-1295/1296 Target and the L-703S can be used for aligning rails or guideways during assembly of machine tools to a very high accuracy. It will even measure pitch and yaw angular errors! Ultra fast setups and real-time alignment data means the rails are aligned in no time!

Downloads

- L-703B Engine-Block Self-Centering Bore Alignment Brochure – Rev B2

- L-703/L-705 Laser Borescope Alignment System for Extruders Brochure – Rev D5

- L-703S 4-Axis Lathe & Turning-Center Spindle Alignment Brochure – Rev B5

- L-703SP Surface Plate Calibration System Brochure – Rev B1

- L-703S 4-Axis Lathe & Turning Center Alignment System – How It Works – Rev A2

- T-1295-T-1296 5-Axis Wireless Target Datasheet – Rev A10

- A-221 2-Axis, Small-Bore Target Datasheet – Rev F3

- S-1404 Lathe9 Software Datasheet – Rev E

- S-1407 Multiturn Software Datasheet – Rev-A3

- R-1307B Basic Readout Datasheet -with KS – Rev F2

- Call Us: +1-203-730-4600

- Email: sales@hamarlaser.com

- Website: www.hamarlaser.com