Description

Plane6 Surface Plate Calibration Software

Hamar Laser’s Plane6 Surface Plate Calibration software is designed to quickly guide you through the steps to check the calibration of a surface plate. It features easy to understand screens to quickly get ready for the data taking using the Moody Method. Enter the surface plate dimensions, the edge width, the number of points, the grade, temperature for the upper and lower parts of the plate and Plane6 calculates the measurement point distances along each of the 8 lines. The data sampling is configurable by the user to handle many different environments. The standard sampling rate records a point in about 4 seconds, which is 3-4x faster than most electronic levels. After recording, the measurement report is generated and can be printed to PDF for easy emailing to customers or managers.

Applications

Applications include:

- Granite surface plates

- Steel surface plates

- Guideways

Features

Easy 4-Step Process

Plane6 guides the user through the alignment with a 4-step process, designed to record flatness data in the most efficient way. First, enter the plate dimensions, border width and number of points per line. Then choose the grade of the plate. Plane6 automatically loads the overall flatness tolerance for that size plate.

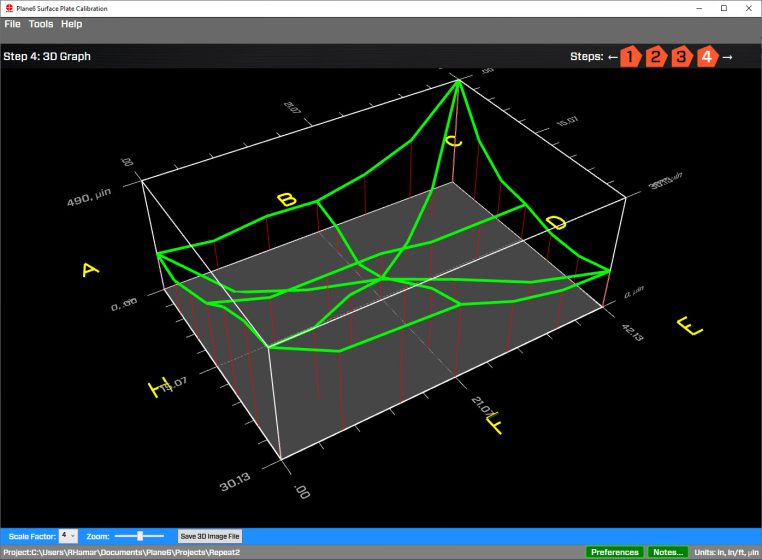

Next, go to Step 2 Data Collection and select the line you want to measure. Plane6 automatically calculates the measuring point dimensions and displays the dimension for the next point. Record the value and Plane6 jumps the position to the next point and shows the dimension for it. Continue until all the lines are measured. Then go to Step 3 Results to see the overall flatness and also the data tables for each line. To see a rotatable graph of the overall plot, go to Step 4 Graph.

Program Features – 4-Step Process

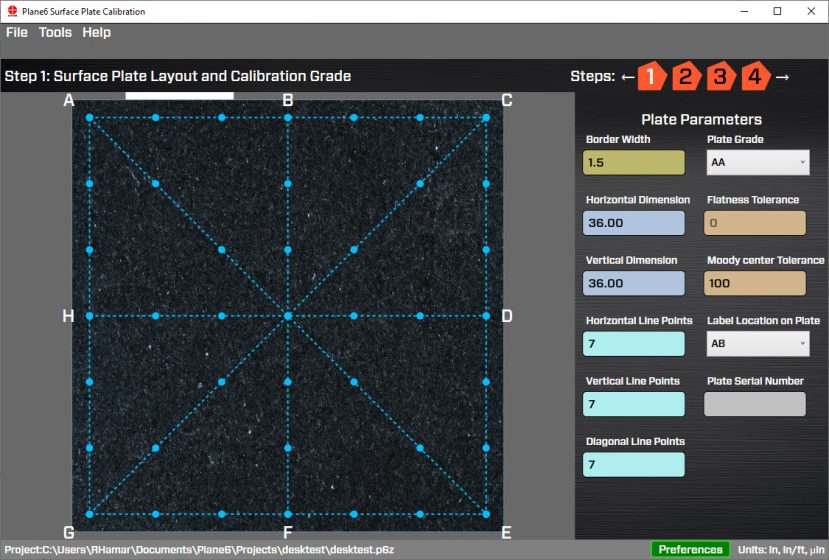

Step 1: Set Up

Enter the plate dimensions, border width and number of points per line. Also choose where to locate the name plate. Then choose the grade of the plate. Plane6 automatically loads the overall flatness tolerance for that size plate.

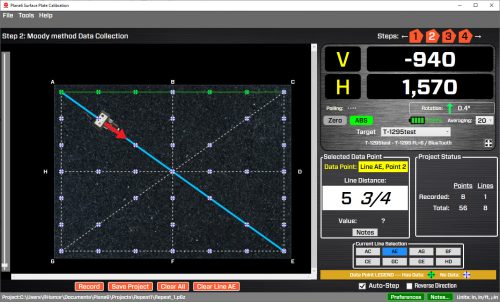

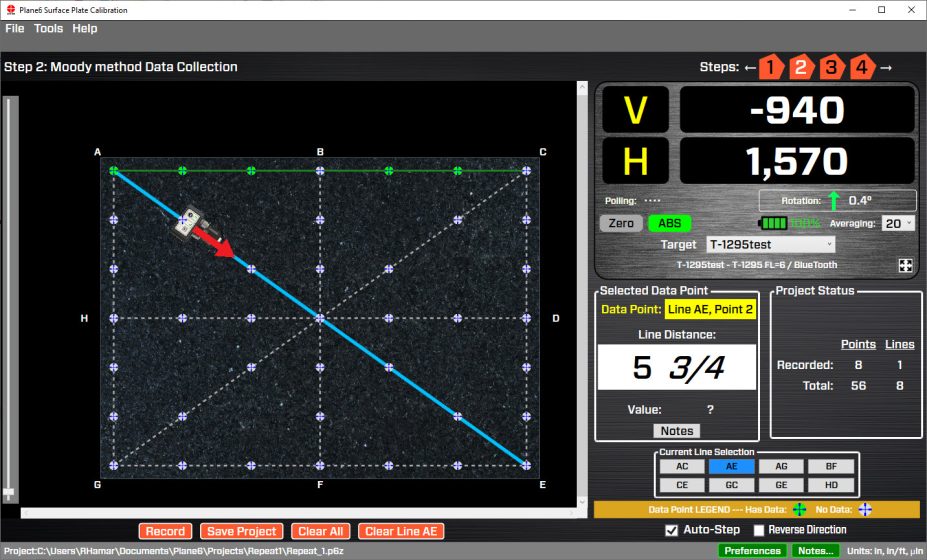

Step 2: Data Collection

Step 2 – Data Collection is where you select the line you want to measure. Plane6 automatically calculates the measuring point dimensions and displays the dimension for the next point. It features a real-time data display with adjustable sampling rate. Record the value and Plane6 jumps the position to the next point and shows the dimension for it. The recorded point icon changes color to indicate data has been taken. Continue until all the lines are measured. You can reverse the direction of the data taking for a given line and retake any point. A target icon tells you what point you are on and what direction its going. Hover over or click on a point to see the value recorded.

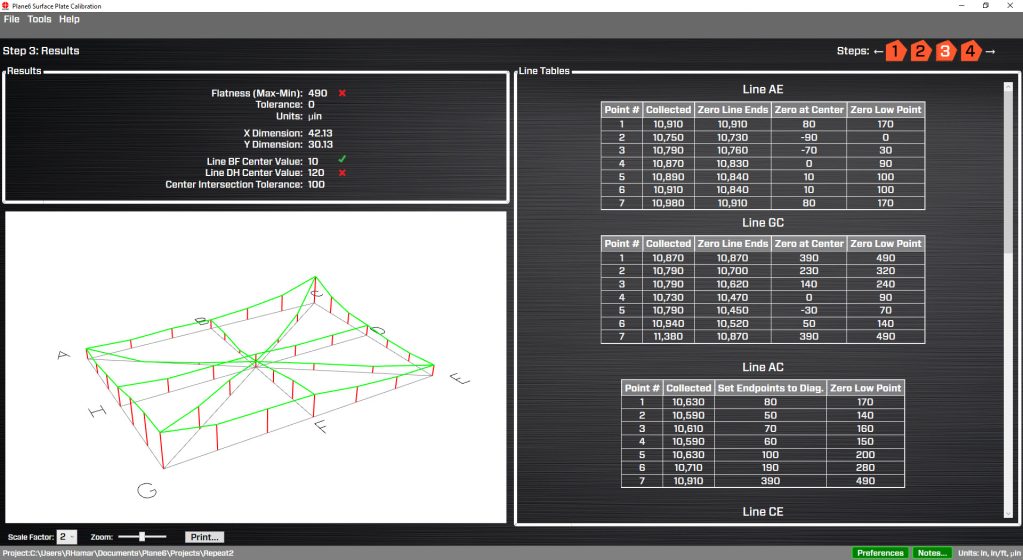

Step 3: Results

Step 3: Results shows the plate grade tolerance, dimensions, units, overall flatness of the surface plate and whether it is in or out of tolerance. It shows a graph of the flatness of each line and also displays the data tables and calculations for each line. You can also zoom in on the graph.

Step 4: User-Adjustable Graph

To change the view, zoom in and out and to increase the scale factor, Step 4 allows the user much more control over the graph. When printing, Plane6 remembers how the graph was set when you printed the report.

Specifications

Drawings

- Call Us: +1-203-730-4600

- Email: sales@hamarlaser.com

- Website: www.hamarlaser.com