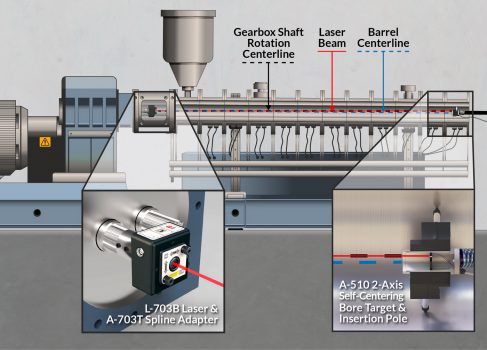

Our 50 years of alignment experience went into the design of the L-703B Twin-Barrel Extruder Laser Alignment Borescope that makes checking the alignment of extruder barrel sections to gearboxes much easier and much faster:

- New, smaller laser fits into tight spaces around the gearbox shafts.

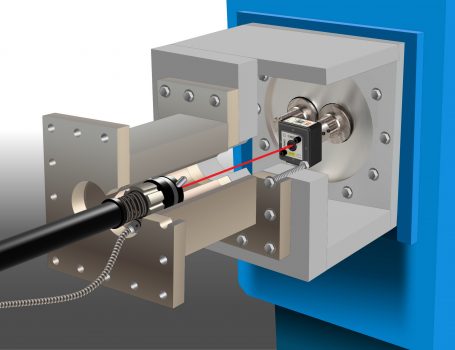

- Uses A-703T Customized Spline-Shaft fixture to mount the L-703B on the gearbox shafts for ultra-fast setup.

- Aligns extruders up to 70% faster and up to 3x more accurate than conventional or optical borescope methods.

- Setup < 20 minutes. Data in 5 minutes after that!

- Uses self-centering bore adapters that find the bore center without any moving parts. No 0º and 180º measurements, so it takes just 5-10 seconds to get a measurement!

- Customized bore adapters with a large range of barrel IDs from 1.18 to 18 in. (30 to 458 mm).

- Readout display resolution of .0001 in. (0.001 mm).

- System accuracy of .001 in. (0.025 mm) in 20 feet (6.1 m).

- Real-time alignment data speeds alignment by showing barrel movements as it’s being adjusted.

- Simple, handheld X-Y readout show the alignment data in the vertical and horizontal axes.

- Horizontal and vertical center & angular adjustments allow for easy alignment of the laser to the gearbox spindle’s rotation axis.

- Battery-operated laser with a range of 50 ft. (15 m).