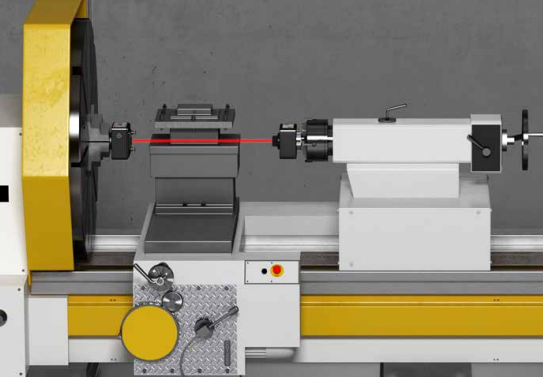

Fast, Ultra-Accurate Machine Tool & Spindle Alignment

Planned or unplanned machine downtime and poorly aligned machines can be very costly. Our ultra-precision alignment lasers can help with both, reducing scrap rates and machine downtime. Ultra-high resolution, combined with intuitive software to correct mounting errors, produces an ultra-accurate and fast alignment system that gets your machines back online, making chips and money.

With an operation similar to optics and other familiar methods, the training requirements are a lot less and the implementation of our system is easier and faster than tradition methods. Built to last, these laser tools are designed to be a great addition to any maintenance department's tool crib.

Hamar Laser has over 55 years of specializing in industry-leading highly accurate laser alignment systems with fast setups and affordable pricing. We are proudly made and serviced in the USA.

There are 2 spindle-alignment systems to choose from:

| Features | L-702SP 5-Axis Machine Tool & Spindle Alignment System | L-703S 4-Axis Lathe & Spindle Alignment System |

|---|---|---|

| Speed | Alignment checks in 15 minutes! | Alignment checks in 15 minutes! |

| Easy to use | Direct Mount into Spindles & Chucks. No Test Bars! | Direct Mount into Spindles & Chucks. No Test Bars! |

| Extremely accurate | Ultra-high resolution of up to.00001 in. (0.00025 mm) | Ultra-high resolution of up to.00001 in. (0.00025 mm) |

| Windows software | MultiTurn10

| Lathe10

|

| Built-in squareness capability | Quickly measure squareness without additional setups | Upgrade to L-702SP for Squareness |

| Alignment Parameters |

|

|

Speed

L-702SP 5-Axis Machine Tool & Spindle Alignment System

L-703S 4-Axis Lathe & Spindle Alignment System

Easy to use

L-702SP 5-Axis Machine Tool & Spindle Alignment System

L-703S 4-Axis Lathe & Spindle Alignment System

Extremely accurate

L-702SP 5-Axis Machine Tool & Spindle Alignment System

L-703S 4-Axis Lathe & Spindle Alignment System

Windows software

L-702SP 5-Axis Machine Tool & Spindle Alignment System

- Easy-to-follow 6-step process

- Helpful graphics and guides

- Real-time alignment data

- Record data on up to 5 linear and 1 spindle axes

L-703S 4-Axis Lathe & Spindle Alignment System

- Easy-to-follow 6-step process

- Helpful graphics and guides

- Real-time alignment data

- Record data on up to 3 linear and 1 spindle axes

Built-in squareness capability

L-702SP 5-Axis Machine Tool & Spindle Alignment System

L-703S 4-Axis Lathe & Spindle Alignment System

Alignment Parameters

L-702SP 5-Axis Machine Tool & Spindle Alignment System

- Flatness, bed twist

- V & H straightness

- Pitch, roll & yaw angular checks

- Spindle axis alignment to sub-spindles and tailstocks

- Spindle axis alignment to guideways

- Squareness of cross-slide/machining axes

L-703S 4-Axis Lathe & Spindle Alignment System

- V & H straightness

- Pitch & yaw angular checks

- Spindle axis alignment to sub-spindles and tailstocks

- Spindle axis alignment to guideways

- Squareness of cross-slide/machining axes

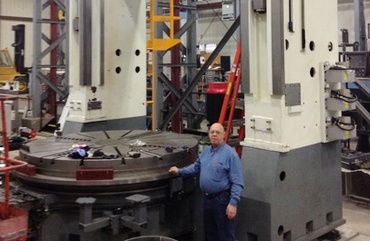

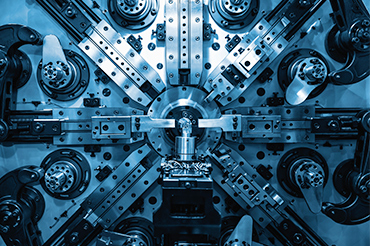

L-702SP Applications

- HBMs and HMCs

- Lathes

- MultiTurns

- Spindle-to-Bore on HBMs

- Turning Centers

- VMCs and VTLs

L-703S Applications

- Lathes

- MultiTurns

- Spindle-to-Bore on HBMs

- Turning Centers

Reduced Alignment Downtime

Faster alignment checks with reduced setups and real-time

alignment data.

Ultra-Accurate Measurements

Resolution to 0.25 microns. Accuracy up to 0.0013 mm/m.

Years of Experience

We know what works…and

what doesn’t. Try us and see!

Advantages vs. Interferometer Methods Expand +

- Same ultra-high accuracy but easier and faster to setup

- Up to 50% faster alignments

- No do-overs due to "breaking the beam"

- Quick alignment "spot checks" vs. whole-axis measurements

- Re-align machines with real-time data updating vs. static measurements

- Squareness measurements are built into the lasers, avoiding setup of finicky “squareness optics”

- Simultaneous multi-axis alignment checks vs. single-axis checks

- Check alignment of guideways and columns without machine power

Advantages vs. Traditional Methods Expand +

| L-702SP | L-703 | Traditional Methods | |

|---|---|---|---|

| Machine Length | Up to 100 ft (30 m) | Up to 50 ft (0.75 m) | Up to 2 ft (0.75 m) |

| Steady Rest Alignment | Yes with no extra setups | Yes with no extra setups | Very difficult to do accurately |

| Bushing Alignment | Yes with no extra setups | Yes with no extra setups | Very difficult to do accurately |

| Resolution | .00002 in.(0.5 µm) | .00002 in.(0.5 µm) | .0002 in.(5.0 µm) |

| Accuracy | .00005 in.(1.3 µm) | .00005 in.(1.3 µm) | .0005 in.(13.0 µm)using .001 indicators |

| Ease of Use | Very | Very | Difficult to get repeatable results • bracket sag • staying on test-bar TDC • indicator drag • requires lots of finesse |

What Makes Hamar Better?

Ultra-Accuracy

Our laser planes have a flatness accuracy of up to .000015 in/ft. (0.0013 mm/m), flatter than any competing laser, usually by a factor of 8!

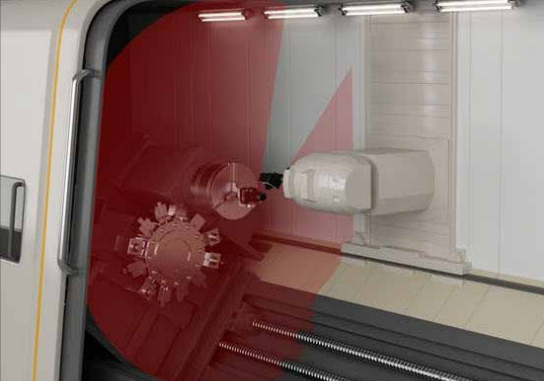

High-Speed Alignments

Renowned for their ease of use and fast setups, our systems significantly speed up alignments with real-time data feedback and simultaneous multi-axis adjustment.

Versatility

With 16 different laser alignment products, we have a laser to fit virtually any alignment application for checking concentricity, flatness, straightness, squareness, parallelism, rotation axis collinearity and spindle tramming.

Alignment Experience

More than 5 decades of alignment experience goes into every product, along with our 28 patents! We know laser alignment!

Innovation

We design innovative laser systems engineered for specific applications, not inferior and under-performing “one-size-fits-all” products.

Service

Family owned and operated, we make and service our lasers right here in the USA, providing our customers with a high level of personal service.

What Our Customers Say

"We shaved a significant amount of time out of our alignment process with Hamar’s system and gained the confidence that we are able to consistently hold the required tolerances.......

Read More...

"Hamar Laser has been a trusted supplier for us for more than 25 years. Our customers and machine manufacturers, such as Wenzel, really like Hamar Laser’s technology. We think anyone that needs highly accurate and very easy-to-use alignment systems...

Read More...

"I want to give you some feedback on our first alignment with our new Hamar system [L-743 Ultra-Precision Triple Scan laser]. We used it to install and align a new bridge mill...

Read More...

"We have been using Hamar laser equipment for about 14 years and have had nothing but great support from your staff all around, Read More...

- L-700 Lathe Alignment System

- L-702SP 5-Axis Machine Tool & Spindle Alignment System

- L-703 Bore, Spindle & Straightness Laser Alignment Systems

- L-705 Bore Alignment Laser System

- L-706 Bore Laser System

- L-706 Small-Bore Alignment Laser System

- L-708 Internal Bore Laser Systems

- L-730 Precision Leveling Laser

- L-732 Precision Dual Scan® Laser