L-743 Laser Outshines Optics in Sawmill Alignments

I’ve got to say Hamar Laser’s L-743 [Ultra-Precision Triple Scan® Laser] is a fantastic tool. It’s fast, it’s accurate. It’s very portable. To do the same amount of three-axis work as the L-743, I’d have to carry three optical scopes with me, which is just not possible.

I started SawPro in 1996 after working in a couple of local sawmills for about 20 years. My work included developing the first variable-tooth pitch and depth band saw blades in our industry in the early ’90s. Today SawPro specializes in developing and training saw filing staff and troubleshooting sawing issues, and we analyze, repair and align machine centers to maximize productivity for customers on four continents and across the U.S.

Always looking to improve efficiency, I began looking into lasers. Because of errors from dust and heat that I saw in some lasers, I shied away from using them until I ran across a Hamar in the field. A service outfit with an L-743 and I were both hired to do similar jobs in the same sawmill, and this let me compare the laser with my Brunson [76-RH Telescopic Transit Square].

The tech with the Hamar L-743 was shooting the feed system and I was shooting the supporting band mill and aligning the band mills and guides. I was really impressed with the incredible accuracy he was getting and that his measurements were very repeatable. What also impressed me was that the L-743 measured in three axes, whereas I had to move my Brunson from one axis to another and buck-in again.

To me, Hamar’s L-743 was like three alignment tools in one and I didn’t have to move out of position at any time. Therefore, the laser was easily three times faster, if not more, than the optical equipment I had been very satisfied with, and so I switched to the L-743. That was many years ago and I’ve had really great success with it ever since.

Recently, I did a head-rig track alignment job for a large sawmill. We had to break 60 feet of track loose, with both flat and “V” rails. This would’ve taken three days with the Brunson but the Hamar let me run two teams. We were within .005 inch in 60 feet, in plumb, level and straight, and were done in only a day and a half. The sawmill, which had struggled with the machine center for a year and a half, almost doubled production. Like many jobs I’ve done with the L-743, this one turned out just fantastic.

Hamar’s L-743: A Great Tool for Sawmills!

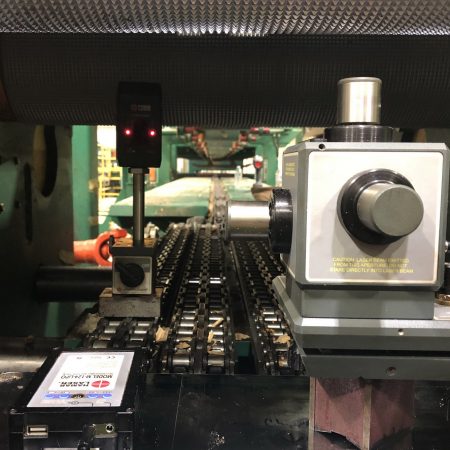

Idaho Forest Group (IFG) is a family-owned lumber producer based out of Coeur d’Alene, Idaho. I am the head filer in the Grangeville mill, one of six sawmills IFG owns and operates in Idaho and Montana. The mill recently got the Hamar Laser L-743 Ultra-Precision Triple Scan Laser and we’ve been using it to align our sharp chain machine center and curve gang line. It’s been working very well, and there are a lot of things we really like about it already.

When we do alignments here, the filers work with the maintenance team and the optimization technicians. All the team members involved really like the repeatability and simplicity of the L-743. It’s a great tool for sawmills! It has 3 automatically sweeping laser planes, so we can set up the laser just once in the center of the machine and get data for elevations on bed chains, anvils and scan chains. We can also check the spike rolls, chipping heads, vertical anvils and bandsaws to our center line in the machine centers. This used to take many more setups and a lot more time using optics. Also, we really like the R-1308 digital readout because we can make adjustments in real time. We’ve been extremely happy with the L-743 and will be using it to align the other machine centers and the planer in the near future.

Sawmill Customer Praises the L-733

Our new L-733 Precision Triple Scan® Laser has been working great in the saw mill where I work. So far we have used it to fix a couple of issues that have plagued our machine for years. I love it!

Our main application is to align machine centers. We have two Chip-n-Saw lines, one large and one small. We also have two edgers. Our alignment consists of making sure our machine line is level, straight (in-line) and square to itself within .005”.

On our small Chip-n-Saw line we had an issue that we thought was due to the outfeed line bar being installed at too high of an elevation compared to the infeed line bar and profile rolls. With the laser we found the infeed line and profile rolls were dropping in elevation, so by the time we reached the outfeed line bar we were running into it. We also found our profile roll box was out of square, which made it impossible to set both rolls square to our feed.

I like that the L-733 lets us shoot straight, elevation and square measurements in just one or two steps, and that it gives us real-time numbers. This is extremely helpful when having to move something back in line. I also like your R-1308 plug-in digital readout that attaches to the target for taking measurements, especially when we are moving something, because there is no delay. I can see the data right away.

I had a couple of questions with the PDA, but your customer support team got me lined out on how to work it. There is a bit of a learning curve for some of our millwrights but the laser is easy to use and they are coming around fast. Overall the laser is a really great tool. If I have any issues, I will contact you and your team. Thank you!

L-743 Leveling Sawmills Log Rollers

Sawmill Alignment Quickly Pays for Itself with Better Recovery

The payback is pretty high using laser alignment techniques. Based on my customers’ results, they see that better recovery and other benefits can make precision alignment pay for itself very quickly. Most sawmills have accepted lasers. Laser alignment works so well, we don’t have to convince anyone anymore. The sawmills just call us up now, and we have been very busy!

Sawmill Alignment: Changing Skeptics into Believers

We’ve been using a Hamar Laser alignment system for 15 years. When anybody sees it in action, they see how accurate it is, how it shows alignment data in real time and how easily the results can be repeated. After that, well, the skeptics become believers.

- L-700 Lathe Alignment System

- L-702SP 5-Axis Machine Tool & Spindle Alignment System

- L-703 Bore, Spindle & Straightness Laser Alignment Systems

- L-705 Bore Alignment Laser System

- L-706 Bore Laser System

- L-706 Small-Bore Alignment Laser System

- L-708 Internal Bore Laser Systems

- L-730 Precision Leveling Laser

- L-732 Precision Dual Scan® Laser