Hamar’s L-743: The Best Alignment Tool, Period

Most of my 20 years of professional machine tool experience includes rebuilds, relocations and retrofits of very large machines that need extremely precise alignment and calibration, and I am familiar with many kinds of alignment tools. I have successfully used Hamar Laser’s L-743 [Ultra-Precision Triple Scan® Laser Alignment System] on almost every one of these projects. I believe Hamar’s L-743 is the best alignment tool on the market and really the only solution for proper alignment of large machine tools.

I was Vice President of Engineering at Team Machine Tools in Mississauga [Ontario, Canada] for 15 years, then retired and founded Vital Machine Tools and Automation in Richmond Hill in 2016. I provide my customers with expert consulting in virtually every aspect of machine tool and automation services, including retrofit, upgrade, alignment, calibration, and troubleshooting. At Team Machine Tools, we used Hamar Laser’s L-743 for 80 percent of our machine relocation projects and machine condition checks and realignments. I fell in love with the L-743 the first time I saw it in action at a customer’s place in Pennsylvania. Now I use only the L-743 in my work.

This tool perfectly covers all machine geometry alignment and check tasks: leveling, parallelism, straightness, flatness, and squareness. Hamar’s L-743 is the only alignment tool I have seen that has three auto-rotating and square laser planes. So, when you’re setting up the laser on these big machines, 90 percent of the time you can set up in one place and then do all the checks and alignments to the machine without having to move any equipment. When relocation is necessary, this is very quick and easy. I think this is the most important difference compared to other alignment tools.

There are other differences, too. Technology is moving ahead today, and we have new equipment on the market which can do alignments, but not as well as Hamar tools. Laser interferometers are sensitive to laser beam breakage. If something accidentally crosses the laser beam you need to start the checks all over again. And we have laser trackers, but I did not have a good experience with them. Yes, some new tools may do a fair job, but they are much more expensive and complicated. You need special knowledge and skill, and the software is harder to use. Hamar systems are very user friendly, and the software tells you exactly what is going on. You can see the alignment data right away and make adjustments in real time.

Over the years I have managed projects for many large machine types using Hamar Laser’s L-743. These range from machines like Toshiba’s floor-type horizontal milling and boring machine to very large machines like a Dorries 13.2m vertical turning lathe – one of the largest machines in North America, and an Ingersoll 15m gantry-type milling machine. The larger the machine tool, the greater the advantages of using the L-743.

The way we align all these machines is very similar. We set the machine base on the foundation, set square and parallel between major components, assemble the machine and then do the full calibration. The L-743 always performs all these tasks much more easily and much faster than any other equipment I have used. In every case, Hamar’s L-743 let me complete these jobs very effectively and efficiently to the customer’s complete satisfaction.

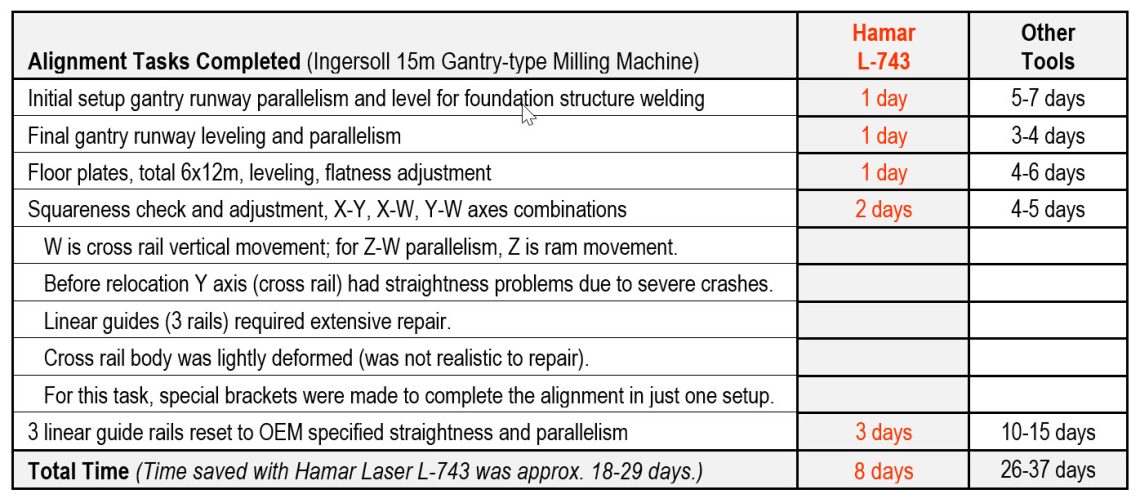

The large Ingersoll machine relocation job was one of the best examples. The gantry runways were 15m with actual machine stroke 10m, and inside distance between columns 8m. The cross rail was the CNC axis. My partner worked with me, and the job was so critical we had to avoid making any mistakes. The L-743 allowed us to complete all tasks in record-breaking time. [See table, below.] Using conventional and other laser equipment we would have needed from four to seven times more time. Gantry runway parallelism especially would have required much greater time, and we would have needed to design and make some expensive fixtures. We purchased the Hamar laser just before starting the project, and it was mostly paid off by the time we completed the job.

Hamar Laser’s L-743 has been my tool of choice on the many machine tool projects I have successfully completed, and this includes very large machines for which there is no better alignment tool, period. The laser’s clever design was invented by Martin Hamar years ago and is still the best tool for machine alignment. It was a very good design then, and still is. But that’s Hamar Laser – there’s just no other brand name like this one.

Ingersoll Large Gantry-type Milling Machine

L-743 Cuts Bridge Mill Install Time by 2-3 Days!

I want to give you some feedback on our first alignment with our new Hamar system [L-743 Ultra-Precision Triple Scan laser]. We used it to install and align a new bridge mill. It worked better than we expected and was so much easier than the levels [and granite squares] we’ve been using in the past. We leveled and squared the bridge mill with the L-743 in 1.5 days instead of the 4-5 days it would have taken using our old equipment! Based on this time savings, we think we will get a payback in 9-12 months!

Accurate Alignment of Mazak Slant Bed Lathe

Just a note to let you know, we completed alignment of the Mazak Slant bed lathe shortly after you and Guy finished your visit with us. We found the head was out of parallel with the bed along with level and twist in the bed. Using your system we were able to re-level and adjust the machine to accuracies within tenths regardless of position through the length of travel. This is the beginning I was sure we could get to and I appreciate your help in getting there. Now I have to drive this program to a consistent level. This helps greatly. Thanks again!

- L-700 Lathe Alignment System

- L-702SP 5-Axis Machine Tool & Spindle Alignment System

- L-703 Bore, Spindle & Straightness Laser Alignment Systems

- L-705 Bore Alignment Laser System

- L-706 Bore Laser System

- L-706 Small-Bore Alignment Laser System

- L-708 Internal Bore Laser Systems

- L-730 Precision Leveling Laser

- L-732 Precision Dual Scan® Laser