L-706 Bore Laser System

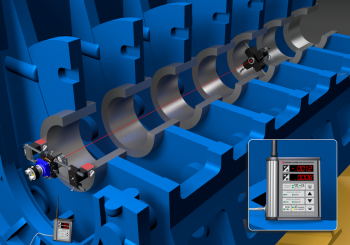

Hamar Laser’s L-706 Bore Laser Alignment System is highly accurate and unparalleled for ease of use. It can handle a wide range of bore alignment and straightness applications. Even extremely difficult bore alignment jobs, such as spherical bearings, can be done easily. The L-706 may be used at distances up to 100 feet, and is recommended for applications with higher pointing-accuracy requirements, such as engine block bore alignment. The L-705 is recommended for applications with lower pointing-accuracy requirements, such as extruder barrel alignments or aerospace hinge lines.

System Highlights

- Fast: 15-minute setup time. Measure each bore in seconds!

- Easy: Unique self-centering adapters are easy to insert into tight spaces and do not need to be inverted (0° & 180°) to calculate results.

- Simple to learn: Use simple X-Y readouts to view the data. No “black boxes” needed!

- Versatile: Many target and adapter options for bore diameters from .250 in. (10 mm) to 40 in. (1 m) or more.

- Bore9 Software: Record bore alignment, calculate straightness results and print reports using optional Windows-based Bore9 Software.

Key Features

- 15-minute setup time. Measure each bore in seconds.

- L-706 Operational Range: 1 to 100 feet (0.2 to 30.5 m).

- Angular adjustment resolution of .001 in. in 100 ft (0.025 mm in 30 m)

- A-514A,B,C Self-Centering Bore Adapters are easy to insert into tight spaces and do not need to be inverted (0° & 180°) to calculate results.

- Adjustable legs fit a large range of bore diameters from 3.75 to 40 in. (95.3 mm to 1 m) or more.

- A-514GS Leg-Setting Gage centers adapters to .0002 in. (0.005 mm).

- R-1307 Readouts with .00001 in. (0.001 mm) resolution update in real time as the bore is adjusted.

- Add a second readout to transmit readings wirelessly up to 200 ft (61 m).

- Optional Bore9 Software aids with setup, records bore alignment data, analyzes the results and prints reports.

- Optional small-bore targets can align bores as small as .250 in. (10 mm).

- Optional spherical-bore target with Virtual-PSD™ technology comes with customized bore adapters for easy and fast alignments.

- Durable rugged, designed to last many, many years of service.

If you do not see your application listed, please contact us to discuss your requirements. We will be more than happy to provide a solution that’s right for your unique alignment problem.

Applications

- Hinge-Line Spherical Bearing Bores

Automotive, Marine & Locomotive Engine Blocks

- Crankshaft and Camshaft Line Bores

- Cylinder Straightness

Manufacturing & Metalworking

- Boring Bar Bearing Alignment

- Deep-Bore Straightness Checks on Cylinder Parts

- Workpiece Bore-to-Spindle Alignment

Marine

- Propeller Shaft Bearing Bores

- Stern Tube Alignment

Military

- Artillery Gun Barrel Straightness Checks

- Extruder Barrel Alignment

- Extruder Bore Straightness and Wear

- Gas Turbines

- Steam Turbines

Highest Bore Alignment Accuracy

Hamar’s bore alignment systems are the most accurate in the industry. Our patented, self-centering targets combined with ultra precise lasers means accuracies down to .0003 in. (0.0075 mm) in 10 feet (1 m) are no problem for our line of bore alignment lasers.

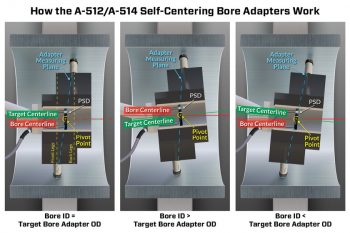

Patented, Self-Centering Target Bore Adapters

Hamar Laser has developed the world’s first self-centering targets (A-510, A-512, T-220, T-221, T-1240) and bore adapters (A-510STA/A-510LTA, A-512STA/A-512LTA, A-514A/B/C, T-221STA) that use no moving parts to self center in a bore. It takes just seconds to position the target in the barrel for an accurate measurement down to .0005 in. (0.01 mm). This eliminates the annoying 0 and 180 measurements needed for typical bore targets.

Widest Range of Bore Diameters in Industry

We’ve been making bore alignment systems for 30 years and have the widest array of targets to check bore alignments with diameters from 1.2 in. (30 mm) to 40 in. (1 m). Most of our targets are self-centering and highly accurate with accuracy down to .0002 in. (0.005 mm) in 10 ft. (3 m).

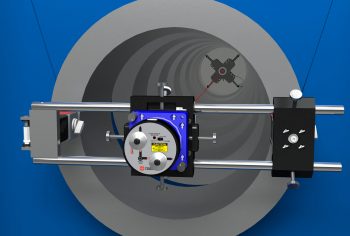

L-111 Laser Stand and L-102 Beam Translator for Maximum Mounting Flexibility

For maximum mounting flexibility, the L-111 Laser Stand and L-102 Beam Translator are used to mount the L-706 either on a flat surface, L-106 Instruments Stand or on the flange of a bore. The powerful magnetic base can be reconfigured to mount the L-111 on vertical or horizontal surfaces. The L-102 Beam Translator uses a parallel-sided piece of glass to center the laser beam on the bore target without changing angle to within .0001 in. (0.0025 mm).

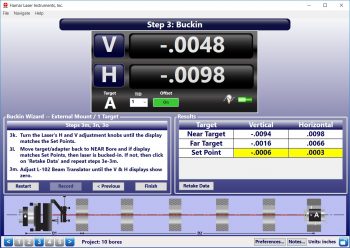

Bore9 Software Records and Analyzes Data

Our Bore9 Software records the bore alignment data, analyzes the results and produces a graph and report on the alignment. A easy-to-follow 5-Step procedure guides the user through the alignment with on-screen help text to aid in training. Bore9 runs on most Windows 7/8/10 laptops and tablets using our A-910-2.4ZB Wireless Radio Receiver to download the data from our R-1307B-2.4ZB Readout

Long-Distance Measuring

The L-706 has 3x finer laser tilting capability than the L-705 for use in long-distance applications up to 110 feet (33 m). The laser beam can be adjusted to .001 in. in 100 feet (0.025 mm in 30 m). Due to the lower angular adjustment range, the L-706 does not work well with lower-accuracy bore applications, such as extruders or hinge-lines, where the L-705 is used instead.

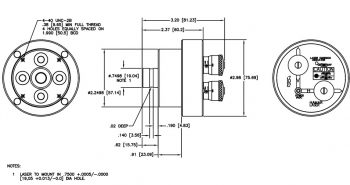

Simple Fixturing for Fast Setup

The L-706 Laser has been designed with a .750 in. (19 mm) mounting stud and flat face with magnets to hold it flush to fixturing. Since the laser beam is concentric to the OD to within .0005 in. (0.01 mm), a simple flat face and .750 in. (19 mm) hole on center is all that is needed to hold the laser (the extruder package includes a self-centering chuck fixture). In fact, the laser replaces the first reference target that a typical borescope would need.

Downloads

- L-706 Engine Block Crankshaft Bore Brochure – Rev C

- L-111 & L-102 Datasheet – Rev D

- R-1307B Basic Readout Datasheet -with KS – Rev F2

- R-358 A-910 A-910ZB Computer Interfaces- Rev H

- T-1218 Datasheet – Rev F

- T-1220 Datasheet – Rev D

- T-219 Datasheet – Rev B

- A-220 Datasheet – Rev G

- T-271 Datasheet – Rev B

- S-1403 Bore9 Software Datasheet – Rev B

- Call Us: +1-203-730-4600

- Email: sales@hamarlaser.com

- Website: www.hamarlaser.com

- L-700 Lathe Alignment System

- L-702SP 5-Axis Machine Tool & Spindle Alignment System

- L-703 Bore, Spindle & Straightness Laser Alignment Systems

- L-705 Bore Alignment Laser System

- L-706 Bore Laser System

- L-706 Small-Bore Alignment Laser System

- L-708 Internal Bore Laser Systems

- L-730 Precision Leveling Laser

- L-732 Precision Dual Scan® Laser