- Hamar Laser is Exhibiting at IMTS 2024!

August 6, 2024

Showcasing world-renowned laser systems for virtually any alignment challenge

The alignment specialists at Hamar Laser Instruments are very excited to be exhibiting once again at IMTS 2024, the world’s largest trade show of its kind.

This year IMTS will be held September 9-14 at McCormick Place in Chicago and we will be there, in Booth 134628 in the Quality Assurance Pavilion (East Building, Level 3).

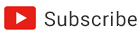

Our demo team will be showing off many of our latest alignment systems, including our versatile, next-generation L-703 Series lasers. The show will be a great opportunity to also talk with Rod Hamar and our alignment specialists about your unique alignment challenges.

NEW for IMTS 2024! In 2022, we introduced the first package of our next-generation L-703 Laser. Since then, we’ve introduced several powerful NEW alignment systems to help you tackle many challenging alignment scenarios better, faster and more reliably, with far less hassle and expense than competing systems and conventional methods:

- L-703B Self-Centering Bore Alignment System – Up to 70% faster than traditional methods, the L-703B checks bore concentricity (alignment) for engine blocks, compressor bores, cylinder bores, shaft bearing bores, stern tubes and more.

- L-703B Twin-Barrel Extruder Alignment Borescope – Small and compact, the L-703B fits into the tight spaces of twin-barrel extruders to align the barrels to gearboxes and to check for barrel wear.

- L-703S 4-Axis Lathe & Turning Center Spindle Alignment System – Coupled with our high-resolution, wireless T-1296 5-Axis Target, the L-703S quickly and very accurately aligns headstock spindle axes to guideways and sub-spindles and tailstocks on lathes, OD/ID grinders, turning centers, and similar machines.

- L-703SP Surface Plate Calibration System – Our latest offering, the L-703SP is a highly repeatable calibration system, offering extremely high resolution and accuracy, easy setup and training, and fast data collection that is up to 30% faster than electronic levels.

We’ll also be showing off our X-SeriesTM Laser Shaft Alignment systems, including our top-of-the-line X-880 / X-990 5-Axis Laser Alignment Tool, which features the highest accuracy in the industry and the least amount of training required to get proficient. Each X-Series™ system includes:

- 5-Year Unconditional Warranty

- Lowest Cost of Ownership in the Industry

- Only Dual-Beam™ Unidirectional Laser System on the Market

- No-Hassle Feature Ad-Ons and Accessory Upgrades

We love alignment challenges!

We’ve been at this for more than 57 years and know a thing or two about alignment! We love alignment challenges so bring your toughest alignment problems and let’s talk about how we can help you solve them.

You won’t want to miss any of the excitement at IMTS, so don’t forget to add Hamar Laser to your Show Planner. See you at the show!

For further information, visit Hamar Laser’s website or contact the company at +1-203-730-4600 or sales@hamarlaser.com.

- End-of-Support Announcement: Windows® 7/8

August 1, 2024

Microsoft has ended support for Windows® 7 and 8 operating systems

Products affected:

- Hamar Laser and X-Series™ tablets and other computer hardware with Windows® 7/8

Effective August 1, 2024, Hamar Laser is no longer supporting Hamar Laser and X-Series™ tablets and other computer hardware with Windows® 7/8.

Microsoft ended support for Windows 7 in 2020, Windows 8 in 2016 and Windows 8.1 in 2023, making it impossible for our Customer Support Team to provide adequate support for Hamar Laser and X-Series™ tablets and other computer hardware with these legacy operating systems. Microsoft no longer provides technical assistance or automatic updates for these operating systems and therefore computers with them are at a higher risk of malware infections and security vulnerabilities.

We will continue to provide support for our customers’ software issues as before, but we can no longer help customers with tablets and other computer hardware running Windows 7 and Windows 8. Some of our proprietary software packages run on tablets supplied by Hamar Laser Instruments, including our X-Series™ tablets, and on other computer hardware meeting the minimum requirements, which gives our customers several options.

For affected Hamar Laser and X-Series™ customers, we recommend these options. Our customers may:

- Upgrade their older tablets (if available) to Windows 10 or Windows 11;

- Purchase new Hamar Laser and X-Series™ tablets (supplied with Windows 11); or

- Obtain their own tablet, laptop or computer meeting the minimum requirements (see lists, below).

Hamar Laser Instruments Software Requirements

Operating System Requirements: • Microsoft Windows Version 10/11 Professional

Computer Requirements: • Physical memory (RAM): 8 GB minimum

• Processor (CPU): Intel i3 or later version or AMD equivalent, 1.3 GHz minimum speed

• Storage: 128 GB internal hard drive space

• Display: Video resolution of 1366 x 768 or better with hardware acceleration and dedicated video memory

• USB: Two (2) 2.0 or higher USB ports

X-Series™ Couple6 Software Requirements

Operating System Requirements: • Microsoft Windows Version 10/11 Professional or Enterprise (English Windows)

• Microsoft .NET 4.5 Framework

Computer Requirements: • Physical memory (RAM): 8 GB recommended

• Processor (CPU): Intel Pentium quad core or later version or AMD equivalent, 2.0 GHz minimum speed. Preferred recommendation: Intel i5 CPU or higher

• Storage: 6 GB internal hard drive space, 10 GB or better for more adequate file storage space (for Couple6 software storage)

• Display: Video resolution of 1920 x 1200 minimum (64-bit color) with hardware acceleration and dedicated video memory

• Bluetooth 4.0 or higher

• Rear facing camera (optional if license feature has the camera option)

Please contact our Sales Department at sales@hamarlaser.com or 1-203-730-4600 (ext. 114) with any questions, and for details and pricing for replacement Hamar Laser and X-Series™ tablets.

- End-of-Life Announcement: R-1357-2.4ZB & R-1357-2.4XBE PDAs

May 6, 2024

We’re replacing our existing PDAs with new higher-performance models

We want to share with you this end-of-life information regarding our rugged PDAs, including replacement part numbers for these products, as outlined below.

Products affected:

R-1357-2.4ZB Rugged PDA Data Display

R-1357-2.4XBE Rugged PDA Data DisplayEffective May 6, 2024, Hamar Laser is discontinuing the R-1357-2.4ZB and R-1357-2.4XBE Rugged PDAs. The computer hardware is being discontinued by our supplier. We will continue to support the Zigbee radio modules and will do our best to support the computer PDA for as long as the supplier continues to support it. Please refer to the table, below, for replacement parts.

End-of-Life Product Replacement Part Number 1. R-1357-2.4ZB Rugged PDA Data Display R-1358-2.4XBE Android* Rugged PDA Data Display with Read16 Android Software 2. R-1357-2.4XBE Rugged PDA Data Display R-1358-2.4XBE Android* Rugged PDA Data Display with Read16 Android Software * Note: Hamar Laser’s Read16 Android Software is required. The new PDA will not run Read9 or Read15 PDA software programs. The new R-1358-2.4XBE integrates a powerful and ultra-rugged PDA with Hamar Laser’s Read16 Android Software. Offering a higher level of performance than its predecessor, the new PDA works with Hamar’s A-1519 and A-1520 wireless targets and its entire line of lasers, including all L-740 / L-730 series auto-rotating lasers and L-702SP combination laser.

Please contact our Sales Department at sales@hamarlaser.com or 1-203-730-4600 (ext. 114) for details and pricing for these replacements.

- Hamar Laser Unveils Surface Plate Calibration System

October 13, 2023

Fast and highly repeatable geometry laser system greatly reduces calibration time and offers many advantages over conventional methods

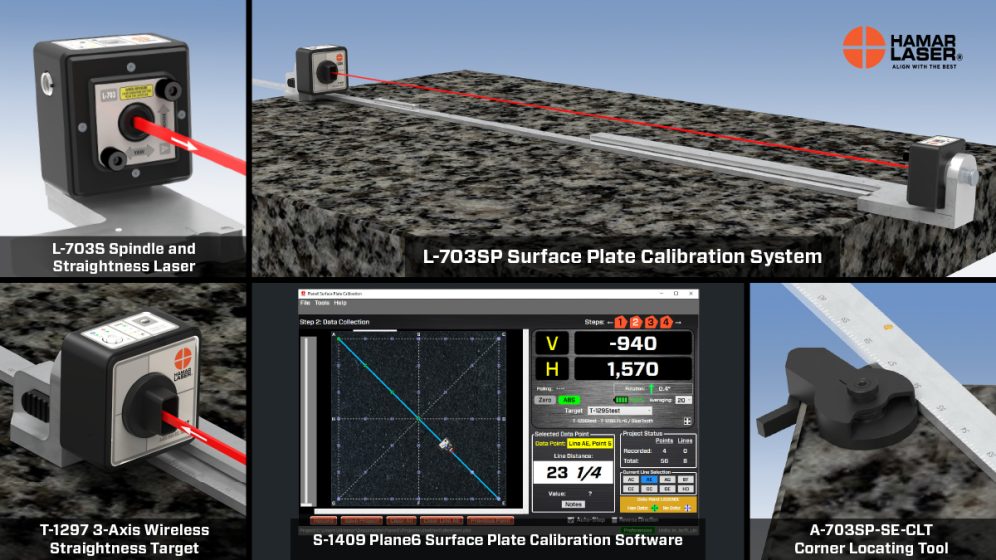

Hamar Laser Instruments has released its L-703SP Surface Plate Calibration System. The L-703SP is a compact geometry laser-based calibration system that is highly repeatable, offers extremely high resolution and accuracy, easy setup and training, and fast data collection. R&D and field testing have shown that the L-703SP significantly reduces the time for calibrating surface plates by 30-60% versus conventional methods.

During the design process, Hamar Laser worked with a calibration laboratory to find out what was most frustrating and time-consuming with the lab’s existing methods. “One of the biggest problems the lab faced with electronic levels was poor repeatability between technicians,” said Rod Hamar, president of Hamar Laser Instruments. “So, we not only worked on creating the best laser and measuring target we could, but we also invested a lot of time on the supporting fixtures to make the L-703SP as repeatable as possible, but also as fast as possible. In our testing on a 4×6 ft. plate, we are seeing overall flatness repeatability of about 20x over the A-grade plate tolerance according to the ASME B89.3.7 standard, Granite Surface Plates.”

The L-703SP System offers many advantages over conventional methods. It is 30-40% faster than electronic levels, more rugged and reliable, and more repeatable from one tech to the next. In addition, the L-703SP is set up directly on surface plates, so each line segment setup is much easier than autocollimators and laser interferometers, which require floor mounting and touchy setups. This results in 50-60% faster plate calibrations and, unlike these devices, does not require re-taking data if the laser beam is broken.

“This is a very exciting new metrology market for us,” continued Hamar. “With its many distinct advantages, our L-703SP will help high-volume calibration companies significantly increase the number of calibrations they can do annually, and it will also help internal calibration and metrology departments to streamline their processes.”

The L-703SP System uses Hamar Laser’s newly designed next-generation L-703S Spindle and Straightness Laser and T-1297 3-Axis Wireless Straightness Target. Compact and lightweight, the new laser is ideal for high-resolution straightness applications, such as surface plates, machine-tool guideways, and spindle axes. The T-1297 target features a super-linear, 2-axis PSD (Position-Sensitive Detector) with resolution of 10 μin. (0.25 μm) and mechanical repeatability of ±10 μin. (±0.25 μm).

A-703SP-LM Laser Mount with L-703S Laser and T-1297 Target The L-703SP features new Windows-based Plane6 Surface Plate Calibration Software, which offers an easy-to-follow, 3-step calibration procedure and built-in tolerance table that speeds setup and data-taking, and generates a full-color report. The system also includes the A-703SP-LM Laser Mounting Fixture, A-703SP-SE Straight Edge & Ruler, A-1297-SP High-Accuracy Flatness-Measuring Base, and A-703SP-SE-CLT Corner and Mid-Point Locating Tool. The laser and target are powered by Li-Ion rechargeable batteries with 14+ hours of life and use Bluetooth wireless communication.

For resurfacing surface plates, the L-703SP also features the Lapping Spot-Checker™, a unique time-saving feature allowing users to spot-check the flatness of any line segment in the Moody plot without having to take data for the entire plate. This can save many hours when having to lap-in a plate that is out of calibration.

The L-703SP Surface Plate Calibration System is the latest in an expanding line of applications using Hamar Laser’s compact and versatile next-generation L-703 Laser and replaces Hamar Laser’s L-740 System for surface plate applications. In addition to surface plate calibration and flatness, the L-703SP System measures surface vertical and horizontal straightness, axis vertical and horizontal straightness, and guideway vertical and horizontal straightness.

For further information or to request a free demonstration, visit Hamar Laser’s website or contact the company at +1-203-730-4600 or sales@hamarlaser.com.

- Hamar Laser Rolls Out L-703S Lathe & Turning Center Alignment System

March 13, 2023

Powerful system features “S” variant of compact & versatile new laser; delivers higher accuracy and faster setups, shaving time off alignments

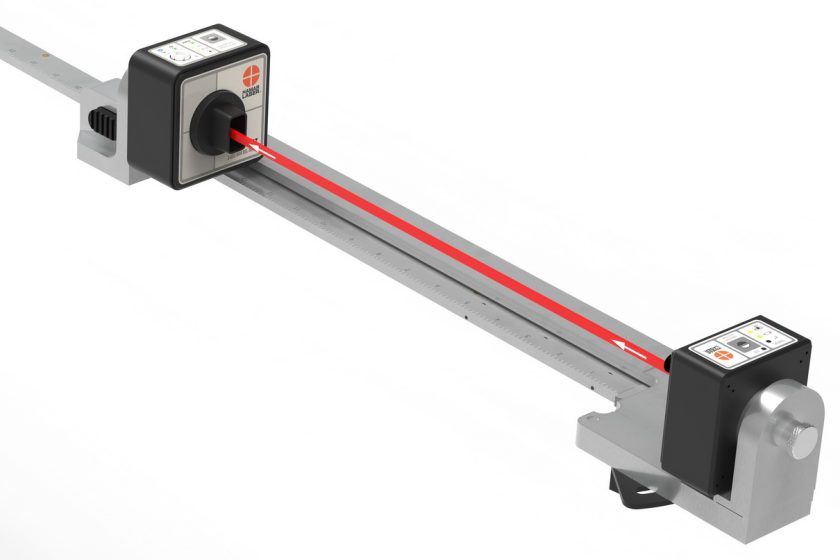

Hamar Laser Instruments announces the release of their new L-703S 4-Axis Lathe & Turning-Center Spindle Alignment System. Featuring the “S” variant of Hamar Laser’s compact and versatile next-generation L-703 Laser, the new system is the latest in a growing family of alignment packages designed for specific applications.

The new L-703S Laser mounts directly into spindle chucks and collets for aligning headstock spindle axes to guideways and sub-spindles and tailstocks on lathes, OD/ID grinders, turning centers, and similar machines. The L-703S may also be used for guideway straightness checks during preventive maintenance and assembly, and for checking surface plates.

“Hamar Laser’s next-generation L-703 Laser design features significantly higher accuracy and a few nice improvements over earlier models,” said Rod Hamar, President of Hamar Laser Instruments. “Our team’s design allowed us to reduce size, cost and complexity, increase accuracy and get rid of annoying wires by adding Bluetooth communications. With a 40% reduction in axial space over our previous L-700 model, the L-703S is much better suited for smaller lathes and turning centers. To top it all off, the price of the new system is significantly less than our older L-700 spindle kit.”

Small and lightweight, the L-703S Laser is ideally suited for all kinds of turning applications, from small CNC turning centers and Swiss-type machines to large-bed lathes. With a range of up to 50 ft. (15 m), the laser can also quickly and easily check the alignment of even very large lathes.

The L-703S System features Hamar’s next-gen T-1296 5-Axis Wireless Spindle & Scan Target, which can easily check all 4 alignment axes of a headstock spindle relative to the tailstock. The T-1296 offers a center resolution of .00001 in. (0.00025 mm) and angular resolution of up to .00002 in/ft (0.002 mm/m). This extremely high level of accuracy can significantly improve machine performance, reduce scrap rates and increase productivity.

The T-1296 Target’s data updates in real time, so alignment errors can be fixed easily and quickly without changing the setup. The new system aligns machines up to 70% faster than conventional methods, such as use indicators and alignment bars. Setup is simple and only minimal training is required.

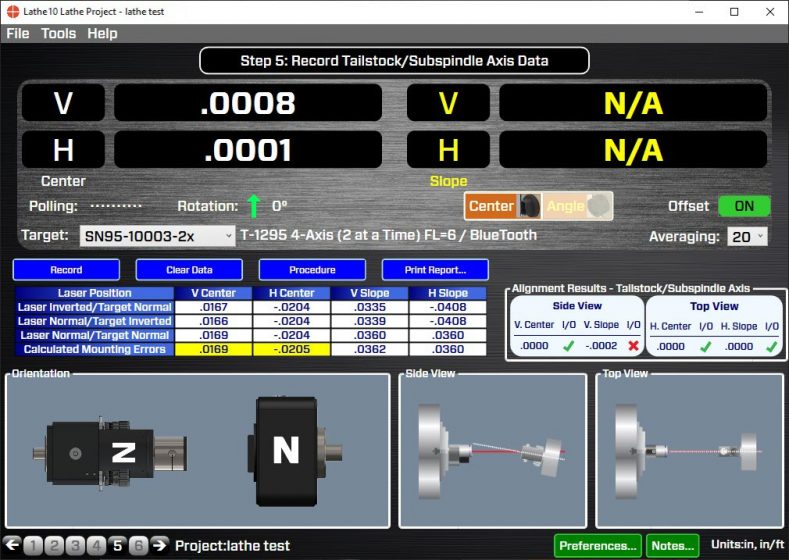

The L-703S System package typically includes Hamar Laser’s T-1296 Target with 3 in. (75 mm) angular lens and new S-1408 Lathe10 Alignment Software for Lathes and Turning Centers. Windows-based Lathe10 uses an Easy-Guide™ system that walks users through spindle alignments in 6 steps and has a 4-axis spindle alignment screen to re-align spindles in real time. L-703S kits can be customized for users’ unique requirements with a variety of accessories and fixtures.

The new L-703S System includes these significant design modifications and features for higher accuracy, greater ease-of-use, and increased speed and versatility:

- Laser Beam: Laser beam size was reduced 30% from the L-700, increasing the measuring range of the target sensors by the same amount. Laser beam centering adjustments were removed, reducing the unit’s size. The laser beam is now pre-centered to the mounting stud to speed setups; higher accuracy centering is available with the optional L-103 Optical Beam Translator.

- Wireless High-Resolution Target: T-1296 5-Axis Wireless Spindle & Scan Target uses Bluetooth communications, eliminating the bulky computer interface and wires that went with it, reducing cost and complexity! The PSDs are enhanced, super-linear sensors for the ultimate in accuracy.

- Power: Now powered by rechargeable Lithium-Ion battery (for up to 11 hours of continuous use), replacing 9V batteries in the L-700; an AC charging adapter can be used for continuous operation.

For further information, visit Hamar Laser’s website or contact the company at +1-203-730-4600 or sales@hamarlaser.com.

- End-of-Life Announcement: 2.4GHz Radios & M-124 Battery

March 10, 2023

Affects some Hamar Laser targets, readers, USB receivers and battery packs

We want to share with you this end-of-life information that affects some of our targets, readers, USB receivers and battery packs. Please note that we have successfully procured replacements for the end-of-life radio components and batteries in the affected products, and have issued replacement part numbers for these products, as outlined below. The new replacement radios are compatible with the old end-of-life radios, so products using both new and old radio components can be used together within a given alignment system.

Products affected:

A-1519-2.4ZB and A-1520-2.4ZB Single-Axis Wireless Targets

R-1307-2.4ZB 2-Axis Readouts

R-1357-2.4ZB Wireless PDA Readouts

A-910-2.4ZB USB Wireless Receivers for PC

M-124-LiPo Rechargeable 9V Battery PackRadios: Effective March 27, 2023, the 2.4GHz radios used in some of our targets, readouts and USB receivers have gone end-of-life and are no longer available. As a result, we are now using replacement radios and antennas in these products and have changed the products’ part numbers. Refer to table, below.

Battery: Effective March 27, 2023, the M-124 battery used in our M-124-LiPo battery pack has gone end-of-life and has been discontinued. We are now using a replacement battery and have changed the battery pack’s part number. Refer to table, below.

The replacement equipment is as follows:

End-of-Life Product Replacement Part Number 1. A-1519-2.4ZB A-1519-2.4XBE 2. A-1519-2.4ZB-NMB A-1519-2.4XBE-NMB 3. A-1519-2.4ZB-2X A-1519-2.4XBE-2X 4. A-1520-2.4ZB A-1520-2.4XBE 5. A-1520SH-2.4ZB A-1520SH-2.4XBE 6. A-1520SH-2.4ZB-NB A-1520SH-2.4XBE-NB 7. R-1307W-2.4ZB R-1307W-2.4XBE 8. R-1307B-2.4ZB R-1307B-2.4XBE 9. R-1307-2.4ZB R-1307-2.4XBE 10. R-1357-2.4ZB R-1357-2.4XBE 11. A-910-2.4ZB A-910-2.4XBE 12. A-910F-2.4ZB No direct replacement but can be replaced with A-910-2.4XBE 13. M-124-LiPo-LP M-124-Li-Ion-LP 14. M-124-LiPo-SB M-124-Li-Ion-SB Please contact our Sales Department at sales@hamarlaser.com or 1-203-730-4600 (ext. 114) with any questions, and for details and pricing for these replacements.

- Hamar Laser Releases L-703B Self-Centering Bore Alignment System

November 7, 2022

Compact, versatile & adaptable system streamlines alignment of engine blocks, compressor bores, cylinder bores, shaft bearing bores, stern tubes and more

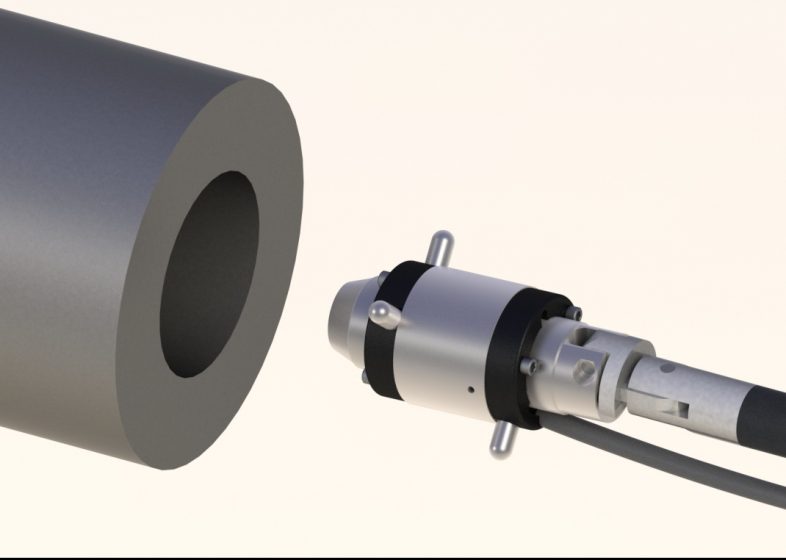

Hamar Laser’s L-703B Bore Alignment Laser, L-112 Laser Mounting Stand and L-103 Optical Beam Translator (exploded view) Hamar Laser Instruments, Inc., a world leader in laser alignment, has released its new, upgraded L-703B Self-Centering Bore Alignment System. The new system uses the L-703B Laser variant of Hamar Laser’s compact and extremely versatile new L-703 Laser which the company introduced in June.

Hamar Laser’s L-703B Self-Centering Bore Alignment System makes bore alignment easier and up to 75% faster than competing systems. The new L-703B Laser replaces the L-705 Laser for applications where the laser is mounted externally. Smaller and lighter than the L-705, the L-703B works with Hamar Laser’s patented, self-centering targets that require only one measurement per bore. Applications include engine blocks, compressor bores, cylinder bores, shaft bearing bores, stern tubes and more.

“In addition to the new bore laser, our L-703B Self-Centering Bore Alignment System includes our new L-112 Laser Mounting Stand and L-103 Optical Beam Translator,” said Rod Hamar, President of Hamar Laser Instruments. “The new laser and accessories facilitate alignments in smaller spaces, speed setups and have allowed us to significantly reduce the package pricing. Rounded out with our patented, self-centering targets, there is no better system than the L-703B for high-accuracy bore alignment.”

In addition to being faster and more affordable, Hamar Laser’s new L-703B Self-Centering Bore Alignment System offers a resolution of .00004 in. (0.001 mm) and much higher accuracy and repeatability than competing products. It is also easier to use and requires less training. A bore alignment survey takes only 15 minutes.

Hamar Laser’s L-703B Self-Centering Bore Alignment System includes these design upgrades:

- Smaller & Lighter—The new design reduces both the size and weight of the laser significantly.

- Adaptable to Other Applications—With different accessories and a firmware upgrade, the L-703B can be adapted to several other applications, such as extruder alignment, guideway alignment, and lathe and spindle alignment.

- Internal Rechargeable Battery—The L-703B now features a built-in rechargeable Lithium-Ion battery with 11 hours of continuous battery life, which replaces the older L-705 Laser’s external battery pack.

- New Laser Mounting Stand—The new L-112 Laser Mounting Stand is significantly improved over the previous L-111 Stand, and now offers horizontal coarse translation and vertical angular adjustment, which greatly speed laser setups.

- New Optical Beam Translator—The new L-103 Optical Beam Translator is much easier to use than the L-102 Translator, its predecessor, and is much smaller, making it easier to fit the L-703B and L-103 into tight spaces.

The L-703B Laser supports Hamar Laser’s entire series of 2-axis cabled bore targets when used with the company’s R-1307 Readouts, and supports Hamar’s R-358 Computer Interface when used with those targets.

For further information, visit Hamar Laser’s website or contact the company at +1-203-730-4600 or sales@hamarlaser.com.

- Hamar Laser Releases Lathe10 Software

October 19, 2022

Completely retooled software supports the newest Windows operating systems

Supports Hamar’s next-gen 5-axis wireless targets and older spindle and scanning targets

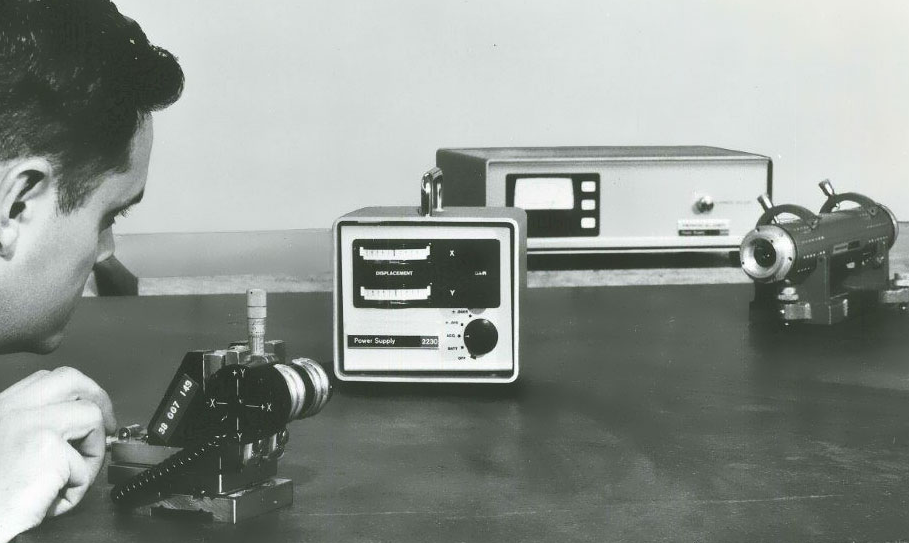

Lathe10 Alignment Software for Lathes and Turning Centers Hamar Laser is pleased to announce the release of Lathe10, the company’s new and completely updated software package. S-1408 Lathe10 Alignment Software for Lathes and Turning Centers supports Hamar’s L-700, L-702SP and L-703S spindle alignment laser systems for aligning lathes or other turning-type machines.

“Our design team did a major rewrite of our Lathe9 to ensure that our programs work with the latest Windows operating systems,” said Rod Hamar, President of Hamar Laser Instruments. “Updated with new high-resolution, high-quality machine graphics, Lathe10 supports our compact, next-gen, multi-axis targets: the T-1294, T-1295 and T-1296 4- & 5-Axis Wireless Targets, as well as our existing A-1519-2.4ZB Scan Targets. Lathe10 also supports our older spindle targets.”

“As part of the update, we added support for measuring pitch and yaw angular errors for the linear axes, as well as support for measuring squareness of lathe cross-slides and multiturn machining axes when used with our L-702SP Laser. The result is a powerful new alignment software package that simplifies lathe and turning center alignment, even on very large lathes.”

Comprehensive and easy to use, Lathe10 utilizes a 6-step process that guides the user through the alignment of lathes and turning centers. An electronic manual is built into the program to aid with learning. All data displays update in real time in up to 4 axes: V center, H center, V angle and H angle. It also records the pitch and yaw angular errors of linear guideways. A printed report shows a summary of the alignment results versus user-defined tolerances, along with graphs illustrating the straightness of the axes.

For further information, visit Hamar Laser’s website or contact the company at +1-203-730-4600 or sales@hamarlaser.com.

- Production Machining Mag Features Hamar’s New 5-Axis Targets

June 27, 2022

Targeting Spindle Alignment for High Machining Accuracy

This 5-axis laser target for spindle and axis alignment offers a fast and highly accurate way to measure spindle alignment, axis straightness and squareness on lathes, multitasking machines, machining centers and ID/OD grinding machines.

Read Article: Targeting Spindle Alignment for High Machining Accuracy | Production Machining

- Hamar Laser to Showcase New Laser Alignment Systems at IMTS 2022

June 15, 2022

L-703–Compact & versatile new L-703 laser systems make aligning bores, lathes and spindles, and twin-barrel extruders easier, faster and more affordable

L-702SP–The L-702SP laser system has been enhanced by unique new, 5-axis, multi-purpose target & mounting fixtures

Hamar Laser will showcase its highly versatile next-generation L-703 Bore & Spindle Alignment Laser System, and its enhanced L-702SP 5-Axis Machine Tool & Spindle Alignment System, at the International Manufacturing Technology Show (IMTS) in September.

“After several rounds of designs to meet our goals of lower cost and more compact form factor, we’ve been very pleased with how many different applications the new L-703 can meet,” said Rod Hamar, President of Hamar Laser Instruments. “We’re in the process of rolling out several new L-703 system packages that we’re excited to show at IMTS.”

“Combining our L-703 and L-702SP lasers with our recently introduced wireless T-1296 Hi-Resolution 5-Axis Multi-Purpose Scan & Spindle Targets has led to an increase in accuracy and performance, while maintaining the ease of use our lasers are known for,” said Hamar.

“In today’s climate of rising prices,” added Hamar, “we’re pleased to offer these systems at a lower price-point that should be attractive to shops looking for an affordable, accurate and faster way to check alignments for PMs or after machine crashes.”

Hamar Laser’s IMTS 2022 Lineup

Multiturn Alignment—Hamar Laser packaged its highly versatile L-702SP 5-Axis Machine Tool & Spindle Alignment System with its new T-1296 Targets to create a compact, streamlined laser alignment system to quickly and accurately align a wide variety of machine tools, from complicated multiturns to lathes and machining centers. In addition to flatness, straightness and squareness, the L-702SP also measures axis pitch and yaw angular errors.

Lathe Alignment—Hamar’s new L-703 4-Axis Lathe & Turning-Center Spindle Alignment Laser System is an ultra-accurate laser that streamlines checking and adjusting the alignment of lathes and turning centers. With a range of up to 50 ft. (15 m), the L-703 can check the largest lathes, where traditional methods are hard to use. It can also quickly check spindle alignment of headstocks to tailstocks or sub-spindles in four axes.

Bore Alignment—Hamar Laser’s new L-703 Self-Centering Bore Alignment System makes bore alignment easier and up to 75% faster than competing systems. Smaller and lighter than the L-705 it replaces, the L-703 works with Hamar’s patented self-centering targets that require only one measurement per bore. Hamar’s new L-112 Laser Mounting Stand has a built-in position control to speed up laser setups. Applications include engine blocks, compressor bores, cylinders, shaft bearing bores, stern tubes and many others.

Other New Systems at the Show—Hamar Laser will also exhibit its recently introduced L-703 Twin-Barrel Extruder Alignment System and its rebranded X-SeriesTM of advanced shaft alignment products (formerly Stealth SeriesTM).

Referred to as “North America’s greatest machine tool show,” IMTS 2022 will be held September 12-17 at McCormick Place in Chicago. Hamar Laser will be exhibiting in the Quality Assurance pavilion in East Building, Level 3, Booth 135427, and is also hosting a Virtual Showroom.

For further information, visit Hamar Laser’s website or contact the company at +1-203-730-4600 or sales@hamarlaser.com.

- Hamar Laser Introduces L-703 Bore & Spindle Alignment Laser

May 19, 2022

Compact & versatile new design excels at hard-to-align twin-barrel extruders

Hamar Laser is pleased to introduce its L-703 Bore & Spindle Alignment Laser, a compact and versatile laser with many applications, including bore alignment, barrel and cylinder straightness, spindle alignments and hard-to-align twin-barrel extruders.

Hamar Laser is pleased to introduce its L-703 Bore & Spindle Alignment Laser, a compact and versatile laser with many applications, including bore alignment, barrel and cylinder straightness, spindle alignments and hard-to-align twin-barrel extruders.“One of our overall design goals is to make our lasers smaller, more versatile and at a lower price whenever possible,” said Rod Hamar, President of Hamar Laser Instruments. “So, when we designed our L-703 to replace our L-706 Bore laser a nice ‘problem’ happened: we found out it quite nicely solved a long-standing application request we’ve had for twin-barrel extruders. Lo and behold, we sold several units before we had finished the design and now have yet another application for this multi-purpose laser!”

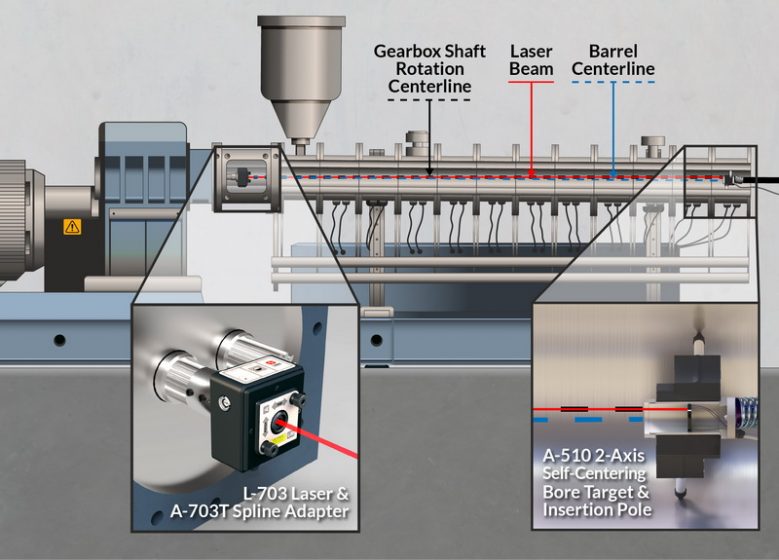

Hamar Laser’s new L-703 is combined with the company’s patented self-centering bore-measuring targets for extruders in the L-703 Twin-Barrel Extruder Alignment System kit, which also includes Hamar Laser’s new A-703T Spline-Shaft Adapter, A-510 2-Axis Target, bore adapters, readout and accessories. Additional L-703 Laser kits for other applications, including bore and spindle alignment and surface plate calibration, will roll out later this year.

Customers who already have the L-705 Extruder Borescope Laser for single-barrel extruders can now align twin-barrel extruders by purchasing just the L-703 Laser and A-703T Adapter and use the rest of the L-705 system components. Designed specifically for the L-703 Laser, the A-703T Adapter positions the laser on the end of the spline shafts on twins for alignments in tight spaces and features an adjustable centering plate to accurately indicate-in the center mounting hole to the rotation axis.

“The small L-703 Laser solves the space-limitation problem that makes aligning twins difficult,” said Hamar. “The laser is short, so it’s easy to use with the typical limited space off the end of the gearbox shaft. This allows the laser to be aligned to the shaft rotation axis so each barrel section can be aligned to a common reference, resulting in much better alignment. This eliminates errors that come from trying to use the outside of barrel sections to check the alignment, since these may not be parallel to the inside.”

“Extruder misalignment causes barrels and screws to wear out quickly and leads to expensive repairs, not to mention causing heavier electrical consumption” continued Hamar. “Our L-703 makes aligning twins much easier and faster so we’re excited about getting this news out to our customers and prospects.”

For further information, visit Hamar Laser’s website or contact the company at +1-203-730-4600 or sales@hamarlaser.com.

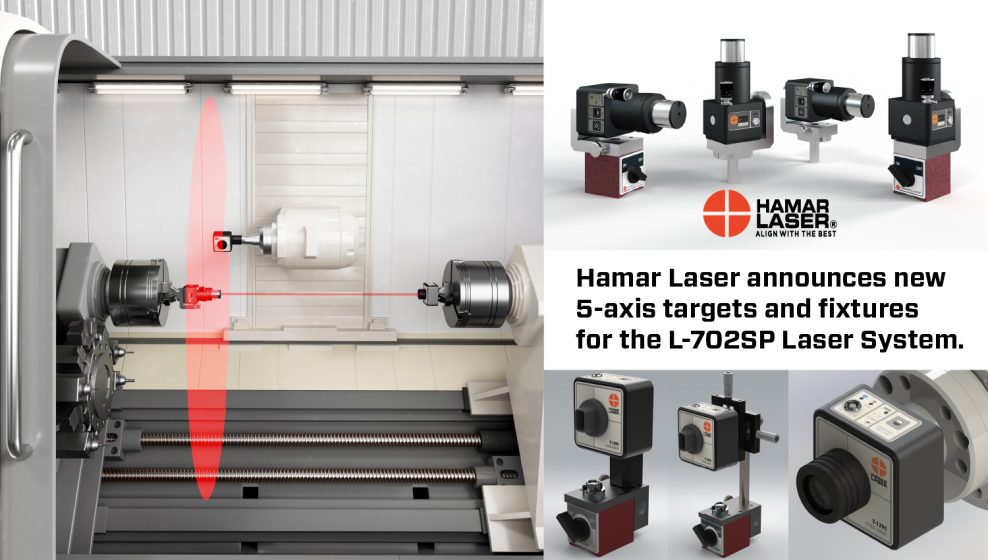

- Hamar Laser Introduces New 5-Axis Targets & Fixtures for L-702SP Laser

March 7, 2022

- Unique T-1295 / T-1296 5-Axis Multi-Purpose Target & mounting fixtures transform Hamar Laser’s L-702SP into an even more capable & versatile laser alignment system

- A single multi-purpose target replaces two targets in the original kit, making the new system more affordable & economical

- Compact system excels at aligning smaller machine tools & multiturns

Hamar Laser Instruments introduces its unique new T-1295 and T-1296 5-Axis Multi-Purpose Scan & Spindle Targets and a suite of new fixtures that transform its L-702SP 5-Axis Machine Tool & Spindle Alignment System into a more affordable and even more capable and versatile alignment system that excels in a wide variety of applications.

Hamar Laser Instruments introduces its unique new T-1295 and T-1296 5-Axis Multi-Purpose Scan & Spindle Targets and a suite of new fixtures that transform its L-702SP 5-Axis Machine Tool & Spindle Alignment System into a more affordable and even more capable and versatile alignment system that excels in a wide variety of applications.“We have never believed in making a ‘one-size-fits-all’ laser system, as our competitors typically offer,” said Rod Hamar, President of Hamar Laser Instruments. “We found that they are never very good for any application. Instead, we have always strived at making the best laser we can for a specific application or group of applications, which is why our lasers are highly praised. However, when the T-1295 and T-1296 5-Axis Targets were conceived, we quickly realized they can transform our L-702SP into that rare laser that does a great job for a wide variety of applications, from lathes to machining centers and many more, so we are excited to bring it market! Our first ‘combo’ laser, as we call it.”

Hamar Laser’s unique new T-1295 and T-1296 Targets offer Bluetooth-wireless communication and are capable of aligning multiple machine axes in three measurement modes: 2-axis center, 2-axis angular and single-axis scanning. Expanding the capabilities of the L-702SP Laser, the T-1295 and T-1296 Targets work with Hamar Laser’s new MultiTurn10 Software and are ideal for many applications, including spindle alignments (center and angular); flatness, straightness and squareness of linear axes and guideways on boring mills, gantries, lathes, machining centers, multiturns and VTLs; injection molding machines; and flatness and straightness of surfaces. They are especially useful on hard-to-align multiturn machines. The T-1296 Target is a high-resolution version of the T-1295 Target for taking ultra-accurate straightness and pitch / yaw measurements.

The new fixture suite is comprised of four mounting fixtures made specifically for the L-702SP Laser and T-1295 and T-1296 Targets to aid in measuring hard-to-check axes on enclosed machining centers, boring mills and multiturns; and includes these fixtures:

- L-702MB Laser Magnetic Base Fixture

- L-702RA Right-Angle Laser / Target Spindle Fixture

- T-242 Target Straightness Measuring Base

- T-243 Target Flatness Measuring Base

Powerful and Economical Combination

Hamar Laser’s L-702SP Laser combines an auto-sweeping laser scan plane with a laser plumb beam and .50 inch mounting stud to insert into spindles. Capable of operating in both scan and beam modes, a single T-1295 or T-1296 Target now replaces two targets in the original L-702SP kit. With the new target, the L-702SP can align all of the axes on hard-to-align multiturns, while its compact size makes it ideal for smaller, enclosed machines and multiturns.

Paired with the new T-1295 and T-1296 Targets and mounting fixtures, the L-702SP is now a more affordable option for budget-conscious customers like smaller machine shops that need to align different machine types but want the ease of use, extremely high accuracy and superior repeatability only a Hamar system can offer.

“The new T-1295 and T-1296 Targets and mounting fixtures have transformed our L-702SP into a streamlined alignment system that has more functionality than our competitors’ systems for the same or lower price,” continued Hamar. “It’s an economical choice for customers who are tempted by lower priced but much less accurate and capable alignment systems. We think we’ve made a great tool even better and we’re excited about getting these into our customers’ hands.”

To learn more, visit our website or contact us at +1-203-730-4600 or sales@hamarlaser.com.

- L-702SP Case Study Featured in CompressorTECH2

January 31, 2022

A just-released case study featuring Hamar Laser’s L-702SP Scan Laser with Plumb Beam has been published in CompressorTECH2, a leading trade magazine for global gas compression products and applications.

“Fair and Square: Using lasers to nail critical QC checks on compressors” was produced with Hi-Tech Compressor and Pump Products, a Hamar customer specializing in compressor service and repair. It reveals how Hi-Tech used Hamar’s L-702SP to resolve complicated and challenging quality control issues the company faced during a large compressor refurbishing project. As shown in the study, Hi-Tech realized a significant return on their investment, as measured in labor savings, reduced machining time, enhanced QC capabilities, additional business from a satisfied customer and expanded market potential.

Read the published case study in CompressorTECH2 (digital magazine), and get the article reprint and step-by-step alignment procedures (downloadable PDFs).

You can also view this case study—and many others—in the Resource Center of the Hamar Laser website (click Case Studies tab).

For further information, visit Hamar Laser’s website or contact the company at +1-203-730-4600 or sales@hamarlaser.com.

- Hamar Laser has announced End of Life for the L-741 Ultra Precision Leveling and Plumb Laser

January 20, 2022

End of Life Announcement L-741 Ultra-Precision Leveling Laser and Plumb Laser

January 20, 2022

Effective February 1, 2022, Hamar Laser Instruments will retire the L-741 Ultra-Precision Leveling and Plumb laser. The replacement parts are getting hard to find and we have focused on developing new laser systems to benefit our customers. We will continue to support our current customers with the L-741 Leveling laser until we can no longer acquire parts.

Below is the recommended replacement laser system.

End-of-Life Product Replacement Part Numbers 1. L-741 Ultra-Precision Leveling Laser with Plumb Beam L-702SP 5-Axis Machine/Spindle Alignment System Please contact our Sales Department at sales@hamarlaser.com (1-203-730-4600 ext. 114) for details.

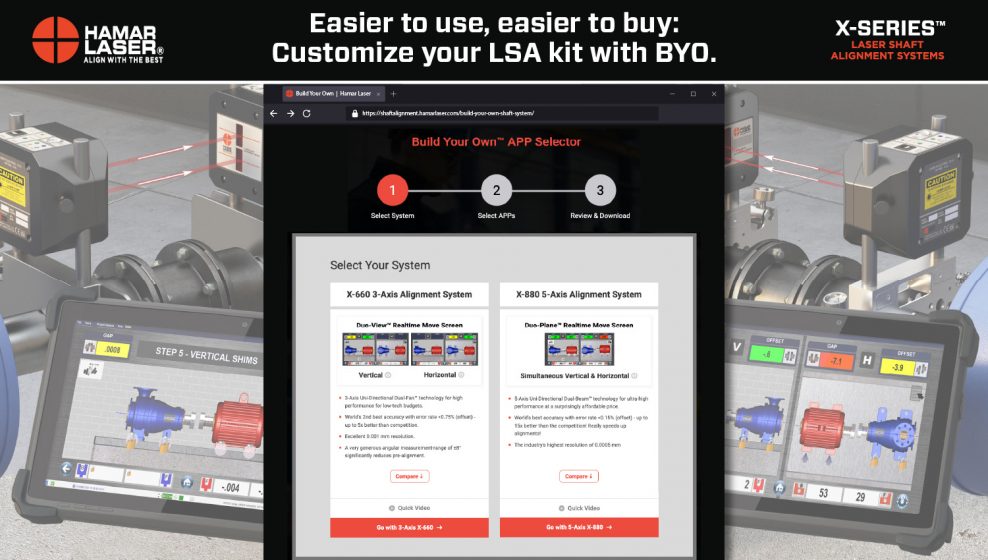

- Hamar Laser Introduces “Build Your Own™” for our X-Series™ Shaft Alignment Systems

December 9, 2021

Our renowned Stealth Series™ line of shaft systems has been rebranded the X-Series™

Hamar Laser proudly introduces Build Your Own™ (BYO), a new way of purchasing shaft alignment lasers which gives our customers the ability to customize shaft alignment kits to better fit their needs. We even added some new geometry Apps and fixtures so our customers can use their shaft alignment kits on geometric applications.

We have also re-branded our renowned Stealth™ shaft alignment systems as X-Series™ under the Hamar Laser brand to be consistent with our other geometric alignment products. Of course, all our customers’ existing Stealth™ systems will continue to be supported in accordance with our standard policies.

“We strive to make maintaining machinery easier with our products, and with BYO we are making the buying process easier, too, allowing our customers to choose exactly what they want in their kits,” said Rod Hamar, President of Hamar Laser Instruments. “The X-Series™ offers unparalleled resolution, accuracy, ease of use and now flexibility. With BYO, our X-Series™ is hands down the best value in the market.”

What is Build Your Own™?

Build Your Own™ (BYO) is a unique, convenient way to get a Hamar Laser X-Series™ shaft alignment system custom-built for your needs. Our easy-to-use online Build Your Own™ App Selector lets you quickly select an X-Series™ X-660 or X-880 shaft alignment system from Hamar Laser Instruments and customize it just the way you want. Choose the rugged tablet, hardware accessories and software Apps you want. While the rest of the market makes you choose from a limited number of pre-selected software packages, BYO lets you select just the Apps and hardware you want.

With our Hamar Laser X-Series™ BYO, you get these advantages:

Accuracy: The most accurate shaft alignment system for your investment.

Flexibility: Choose the hardware and software Apps you need to get your jobs done right today; easily upgrade as needed in the future!

New Geo Apps: We have added several geometry data taking apps: flatness, straightness, manual data recording and timed data recording.

Savings: Save money by buying only the hardware and Apps you want.

Convenience: You get an online budgetary estimate fast with our BYO App Selector.

How does BYO work?

Our Build Your Own™ App Selector guides you through the process in three simple steps:

1) Select 1 of our 2 X-Series™ shaft alignment systems: 3-axis X-660 or 5-axis X-880.

2) Choose from among 27 powerful software Apps, and select the tablet and hardware accessories that are right for your needs.

3) Review and download an online budgetary estimate. If desired, request a firm quote.

The Build Your Own™ App Selector will automatically verify your hardware and software selections, and then e-mail you a budgetary estimate.

Our X-Series™ Build Your Own™ App Selector is truly unique. No other laser shaft alignment manufacturer offers this level of convenience and customization!

To learn more, visit our website or contact us at +1-203-730-4600 or sales@hamarlaser.com.

- Hamar Laser Introduces A-221 Small-Bore Self-Centering Target

January 15, 2021

Ideal for extruder barrel alignment and large-caliber gun barrel straightness

A-221 2-Axis Small-Bore, Self-Centering Target for Bores from 1.18-10 in. (30-255 mm) Hamar Laser is pleased to introduce a new small-bore target. The A-221 Self-Centering, Small-Bore Target is designed specifically to measure the straightness and alignment of small- to medium-size bores, from 1.18 in. (30 mm) to 10 in. (255 mm). This makes the A-221 Target an ideal alignment tool for large-caliber gun barrel straightness, cylinder straightness and small single- and twin-barrel extruder alignment applications.

The small, lightweight, compact A-221 Target self-centers to an accuracy of .0007 in. (0.018 mm) and has a sensor area of 10×10 mm. The new target features self-centering bore adapters with customized legs to fit the bore diameter, but which can accommodate diameter changes of ±.040 in. (1 mm) without affecting the self-centering feature. The target’s 10×10 mm PSD (Position Sensing Detector) is concentric to target OD to within .0005 in. (0.013 mm).

Other features include:

- Measurement resolution of .0001 in. (0.001 mm) when used with Hamar Laser’s

R-1307 Readout. - 5 ft. (1.5 m) insertion pole with connector for extra lengths up to a total of 15 ft. (4.5 m) insertion length.

- Accommodates bores from 1.18 in. (30 mm) to 10 in. (255 mm) when used with customized Bore Adapters.

For further information, visit Hamar Laser’s website or contact the company at +1-203-730-4600 or sales@hamarlaser.com.

- Measurement resolution of .0001 in. (0.001 mm) when used with Hamar Laser’s

- Hamar Laser Releases A-1700 Roll-Leveling Kit

November 20, 2020

High-accuracy electronic level works with Hamar Laser’s L-742 & L-732 laser systems to streamline roll alignments

Hamar Laser Instruments has released its new A-1700 Roll-Leveling Kit. The A-1700 is an accessory kit designed to be used with the company’s L-742 and L-732 Dual Scan® Roll Alignment Systems. It comes with an easy-to-use, high-accuracy electronic level that transmits data wirelessly to Hamar’s R-1357-2.4ZB PDA Display.

“Our A-1700 Roll-Leveling Kit makes accurate roll alignment easier and faster,” said Rod Hamar, President of Hamar Laser Instruments. “The A-1700 gives users the ability to quickly level rolls with a high-accuracy electronic level while using our L-742 or L-732 laser alignment systems to perform the more difficult parts of the alignment.”

“A key feature of our level,” said Hamar, “is that its data is transmitted via Bluetooth to our R-1357-2.4ZB PDA, so users can see both the vertical and horizontal axes of the roll at the same time. This greatly speeds up the alignment and simplifies the process.”

This powerful electronic level offers many benefits over conventional leveling devices:

- High accuracy — Up to 5x higher than standard levels, with a resolution of .0002 in/ft (0.02 mm/m or 0.001°).

- Digital values — Provides digital values that don’t need to be interpreted, like reading the edge of a bubble.

- “Eyes-off” operation — Users don’t need to be looking down on the level to get the data, which can be very difficult in tight spaces and high elevations.

- Real-time data — Data are displayed in real time, so it’s easy to see when the rolls are aligned.

- Wireless transmission — Wireless up to 30 feet means users don’t have to be near the level to get data, making adjustments easier.

The A-1700 Roll-Leveling Kit includes a v-block type mounting base for rolls from 2 to 24+ inches (51-610+ mm) in diameter, and a safety strap to prevent the electronic level from falling off rolls during alignments. The A-1700 can be purchased as part of L-742 and L-732 Dual Scan® Roll Alignment System packages, or separately.

To learn more, visit the Product Catalog in our website or contact us at +1-203-730-4600 or sales@hamarlaser.com.

- Our colorful new Timeline tells the Hamar Laser story!

September 24, 2020

We’ve been pioneers in laser alignment since our founding in 1967 by Martin Hamar, a brilliant and enterprising Cornell-educated engineer with 29 patents to his name today. So it’s no surprise that we’re credited with many industry “firsts,” including these, to name just a few.

- 1976 – World’s first automatically sweeping precision laser plane (Model L-711)

- 1981 – First invisible IR diode-based bore alignment laser (L-800)

- 1990 – First visible diode-based, 4-axis shaft alignment laser (S-640)

- 1992 – Triple-Scan® laser with 3 automatically sweeping laser planes (L-723)

- 1996 – Laser alignment system with both scan plane and square plumb beam (L-720)

- 2000 – First wireless shaft alignment system in the market (S-650)

We’ve just posted a Timeline to our new website that tells the interesting story of Hamar Laser’s 53+ years of innovation and leadership in words and pictures. Check it out!

- New Product Release: R-1357-2.4ZB Android PDA Display

April 8, 2020

Ultra-rugged, next-gen R-1357 PDA features Android OS & versatile Read16 software

Hamar Laser Instruments has released its new R-1357-2.4ZB Wireless PDA Readout. “We’re excited to release this ultra-rugged Android PDA, our first Android product, with more being planned for the future,” said Rod Hamar, President of Hamar Laser Instruments. “With IP68 and MIL-STD-810G environmental ratings and a new rugged design, our R-1357 is our next-gen wireless target data display that will serve our customers for many years to come. It features our new Read16 Android software with updated screens, more familiar operating functions and easier program flows.”

The new R-1357 seamlessly integrates a next-gen Trimble Android PDA with Hamar Laser’s new Read16 proprietary software and a Zigbee® 2.4 GHz RF module offering these features:

- Displays readings for up to 5 single-axis and two 2-axis targets, and the feature-rich package offers mode selections for numerous alignment functions, a laser setup wizard, graphic displays of target readings for roll alignment, a data-taking module, adjustable data averaging, and a data screen that summarizes the target readings.

- Zigbee® uses a frequency-hopping protocol to avoid interference with other devices operating at the same frequency, so 2 or more systems can work in the same area and not interfere with each other.

Available now, the R-1357 replaces the R-1356 and, like its predecessor, the new PDA works with Hamar’s A-1519 and A-1520 wireless targets and its entire line of lasers, including all L-740 / L-730 series auto-rotating lasers and L-702SP combination laser.

To learn more, visit the Product Catalog in our new website or contact us at +1-203-730-4600 or sales@hamarlaser.com.

- Yes, we’re open for business! A COVID-19 update from Rod Hamar

March 25, 2020

We’re open for business!

Dear Customers and Suppliers:

Since the WHO declared the coronavirus a pandemic on March 11, we’ve all seen a slew of unprecedented measures to contain the spread of the virus, including the closings of schools and non-essential businesses. This bizarre landscape seems to be changing daily.

Fortunately, Connecticut, where we are based, has exempted manufacturers from the closure orders and this means we are “Open for Business.” We are taking every step needed to ensure that we can continue to manufacture, service and support your Hamar Geo and Stealth Series™ shaft alignment laser systems during the worldwide crisis.

- Customer support: As always, our dedicated sales, service and support teams are on duty and ready to help you.

- Product sales & service: We are continuing to manufacture, test and deliver our full line of laser alignment systems and accessories, and to promptly handle calibration, servicing, repairs and upgrades of your existing equipment.

- Supplies & parts: Fortunately, our well-established supply line remains healthy and we are currently experiencing only minor disruptions.

- Training: For those with questions, we are setting up online help sessions using GoToMeeting; contact us at training@hamarlaser.com.

Our product line supports many applications, making Hamar Laser an integral part of the vital supply chain for many manufacturers falling within the Department of Homeland Security’s 16 Critical Infrastructure Sectors, including aerospace and defense. We are continuing to operate as an essential business in compliance with federal and state mandates.

In daily operations we’re doing our part to prevent the spread of the virus, including:

- Implementing “social distancing” practices in our office and manufacturing areas, and following rigorous cleaning and sanitizing procedures.

- Expanding our existing remote-work capabilities for business functions including customer service and technical support.

- Monitoring the latest guidance from health officials, and modifying policies and practices as needed.

During the 52 years we’ve been in business we’ve weathered some serious storms, and we expect to weather this one, too! With the many concerns you face at this time, we’re working very hard to make sure you don’t need to be worried about your Hamar alignment systems.

As usual, please don’t hesitate to contact us with any concerns or questions you may have:

- Phone (USA & International): +1-203-730-4600

- Sales & Repairs: sales@hamarlaser.com

- Customer Support: +1-912-673-7279, amy.smith@hamarlaser.com

- Stealth Sales & Support: +1-804-869-5425, ron.sullivan@hamarlaser.com

All around the world, businesses and institutions are mobilizing against the pandemic so I believe we’ll see the end to this crisis soon. In the meantime, thank you for your confidence in us. We’re standing should-to-shoulder with you, ready to help with your alignment needs.

Let’s all stay calm, healthy and optimistic!

Rod Hamar

President

Hamar Laser Instruments

- R-1355-2.4ZB and R-1356-2.4ZB Rugged PDA Discontinued

March 13, 2020

Effective March 15, 2020, Hamar Laser is discontinuing the R-1355-2.4ZB and R-1356-2.4ZB Rugged PDA’s due to the computer hardware being discontinued by our supplier. We will continue to support the Zigbee radio modules and will do our best to support the computer PDA as long as the supplier continues to support it.

The replacement equipment is as follows:

* Note Read16 Android Software is required. The new PDA will not run Read9 or Read15 PDA software programs

End-of-Life Product Replacement Part Numbers 1. R-1355-2.4ZB Rugged PDA Data Display

R-1357-2.4ZB Android* Rugged PDA Data Display with Read16 Android Software2. R-1356-2.4ZB Rugged PDA Data Display

R-1357-2.4ZB Android* Rugged PDA Data Display with Read16 Android Software - Hamar Laser Launches New Website

December 16, 2019

Streamlined, easy-to-use design puts enhanced product information and valuable resources at visitors’ fingertips

Hamar Laser Instruments, Inc., a world leader in laser alignment, announces the launch of its attractive, easy-to-use, information-packed new website: hamarlaser.com.

“Hamar Laser has been designing ground-breaking laser alignment systems for 52 years,” said Rod Hamar, President of Hamar Laser. “With so many innovative products to support online, our old website had become crowded, so we redesigned it to showcase our laser alignment products on an attractive, contemporary website that’s intuitive and easy to use. We wanted to keep the wealth of detailed application information from our old site but make it easier to access. And for those unfamiliar with our products, we added a new slate of training summary videos to make it easier to understand how well our lasers really work.”

Read the news release.

- New Blog Post: L-743 Leaves Laser Tracker in the Dust

December 5, 2019

A sawmill service company says our easy-to-use L-743 Ultra-Precision Triple Scan® laser quickly overcame sawdust and vibration problems that left the operators of the much more costly tool scratching their heads.

- Hamar Laser featured in Timber Processing magazine!

November 13, 2019

With its greater ease-of-use, higher accuracy and excellent repeatability over older methods and so-called “pointing” lasers, a growing number of sawmills are aligning their machinery with our L-743 Ultra-Precision Triple Scan® Laser Alignment System in order to boost their recovery (maximize their yields) and profits. See page 32 of the October issue of Timber Processing magazine (online version), and download a PDF of the article here.

- End of Support (Wireless 900 MHz) Announcement – A-1519-900, A-1520-900 Targets, R-1310-900 PDA Readout, R-1307W-900 Readout, R-1307-900 Combination Readout & A-910-900 USB Radio Receiver.

Effective October 1, 2019, Hamar Laser will no longer support the 900 MHz wireless functions of A-1519-900 and A-1520-900 Type II Single-Axis Scan Targets. We will also be ending wireless support for the R-1307W-900 Wireless Target Readout, R-1307-900 Combination Readout and A-910-900 Computer Interface due to the 900 MHz radios going end of life and our depleted stock of replacement radios. We will continue to support the targets/electronics themselves by replacing the radios with 2.4ZB Zigbee radios and offering replacement PDA’s and Readouts.

The replacement equipment is as follows:

End-of-Life Product Replacement Part Numbers 1. A-1519-900, Type II Single-Axis Targets Note – in most cases, we can replace the radio/circuit card in the existing targets, which avoids having to purchase a replacement unit.

A-1519-2.4ZB Single-Axis Zigbee® Wireless Target 2. A-1520-900 Type II Single-Axis Target Note – in most cases, we can replace the radio/circuit card in the existing targets, which avoids having to purchase a replacement unit.

A-1520-2.4ZB Single-Axis Zigbee® Wireless Target 3. R-1310-900 PDA Readout & R-1310-2.4 PDA Readout Note – in addition to the radios, the standard PDA’s are no longer available, so a replacement unit needs to be purchased.

R-1356-2.4ZB PDA Readout Zigbee® Wireless 4. R-1307-900 Wireless Readout or R-1307-900 Combination Readout Note – in most cases, we can replace the radio/circuit card in the existing readouts, which avoids having to purchase a replacement unit.

R-1356-2.4ZB PDA Readout Zigbee® Wireless or

R-1307W-2.4ZB Wireless Target Readout or

R-1307-2.4ZB Combination Readout.

***5. A-910-900 Computer Interface, A-910-2.4 Computer Interface Note – we may be able to replace the radio/circuit card in the existing interface. Please email us to inquire.

A-910-2.4ZB Zigbee Wireless USB Receiver Please contact our Sales Department at sales@hamarlaser.com, 1-203-730-4600 (ext. 114) for details and pricing for these replacements.

- Hamar Laser to Exhibit at Forest Products Expo

June 21, 2019

Hamar Laser Instruments, Inc. will demonstrate its precision laser alignment systems during the Forest Products Machinery & Equipment Exposition in the Georgia World Congress Center, from June 26 through 28 in Atlanta, Georgia. We’ll be exhibiting in Booth #953.

Change is afoot in the lumber processing industry: Saw mills have begun aligning their machinery with lasers instead of conventional methods like optical theodolites and wire. As many mills are discovering, lasers from Hamar Laser Instruments offer many advantages over these older methods and other laser systems, including greater ease of use, higher accuracy and excellent repeatability.

Hamar Laser Instruments’ L-743 Ultra-Precision Triple Scan® Laser Alignment SystemAt the show, we’ll be exhibiting our L-743 Ultra-Precision Triple Scan® Laser and L-733 Precision Triple Scan® Laser, which feature 3 extremely precise auto-rotating laser scan planes that let users make multiple alignment checks from a single setup. They are ideal for quickly and accurately checking and adjusting all of the most critical alignments in saw mills, including checking log carriages for straightness and flatness/level; checking support rollers for squareness; and checking saw blade squareness, parallelism and plumb.

Come visit us and see for yourself why so many mills are switching to laser alignment!

- Modern Roll Alignment Techniques – Which is Best?

November 28, 2018

Making sense of your roll alignment options

As someone tasked with looking after roll machinery you understand that proper alignment is vital to keeping your equipment operating efficiently and productively.Today, however, you are faced with choosing from among a sometimes confusing array of alignment technologies. In this complex marketplace, choosing the best solution for your particular applications and circumstances can be challenging and time-consuming—and mistakes can be expensive!

- Hamar Laser Digital Library on YouTube

November 27, 2018

Hamar Laser Instruments, Inc. announces it has launched a new Digital Video Library on YouTube. The library features laser alignment training videos that were shot in our Sarasota, FL training center by our 25 year alignment veteran, Darel Ford, who is one of the top experts in the laser alignment industry.

To make it easier to find a video to answer your questions, we have organized the videos into several categories:

- Operational videos – These videos show the basic operations of the major components of our laser systems, such as: laser, target, readout and software. For example, there are videos for the L-743 Ultra Precision Triple Scan® Laser, A-1519-2.4ZB Wireless Target, R-1307B-2.4ZB Readout, the L-111 Laser Stand Assembly, and more.

- Laser setup videos – These are the “nuts and bolts” of setting up a laser alignment system that can be applied to any application. We call aligning a laser to reference points, “bucking-in” or “buck-in”. In this set of videos, you’ll learn about 2-Point and 3-Point Buck-ins with our L-730/L-740 Series Scanning Lasers. These techniques can be applied to our bore and spindle lasers, too.

- Application videos – These videos show how to apply the basic laser setup principles to specific applications with detailed step-by-step instructions. Learn about these main alignment applications: bores, extruders, surface flatness/leveling, gantry-style machine tools, lathes, roll parallelism and more.

And this is just a start as we have more videos coming, such as software and support videos! So keep stopping by for new video updates and please subscribe to our HLI DL Channel.

Digital Library Tablet

And for those who cannot access the internet or would like to have a portable training aide, we are offering a 10-inch tablet pre-loaded with all the training videos, troubleshooting guides from our Hamar Knowledge Base, manuals, application notes and brochures. The tablet has up to 6 hours of battery life to view videos and read through application notes even while “on the job.” Contact us at sales@hamarlaser.com for a quote.Or visit our new Digital Library now!

- IMTS 2018 Show Wrap Up — IMTS 2018 Booth Traffic Up 75%!

September 17, 2018

Hamar Laser’s new spindle alignment lasers and record attendance helped us have one of our best shows in 10 years

By Rod Hamar, President & CEO, Hamar Laser Instruments, Inc.

Hamar Laser has been exhibiting at the International Manufacturing Technology Show (IMTS) for many years and this year’s show was definitely one of our best.

We enjoyed catching up with many of our customers and met a lot of prospective customers who are looking for easier and faster ways to solve a variety of alignment problems. Naturally, we’ve been busy providing information and quotations ever since the show!

Also lending a hand at the show was Guy Laverty, our Midwest Territory Manager for our extensive line of Geometry Products, and Ron Sullivan, our Brand and Distribution Manager for our Stealth Series™ Shaft Alignment Products.

A 30-year industry veteran, Ron Sullivan said the show was massive and overwhelming: “It really blew my mind just how many companies were there, and how much machinery and technology was on display,” he said.

Held in McCormack Place in Chicago from September 10-15, the exhibition was the largest IMTS ever, with more than 2,563 international exhibitors and 129,415 attendees in a vast 1.4 million-square-foot venue. Mark Albert, editorial director of Modern Machine Shop, dubbed it “North America’s greatest machine tool show.”

- L-702/L-702SP Lathe and Turning Center Alignment System

September 13, 2018

The L-702 and L-702SP are new alignment lasers that make aligning lathes, turning centers, etc. very easy and very fast.

- S-1387 Machine Tool Software New Release

September 11, 2018

Analyze and correct machine tool geometry errors – flatness, straightness, squareness and parallelism

- HLI at IMTS to show new L-702/L-702SP Lathe Alignment Laser

September 5, 2018

Come see us at booth 135436 at the IMTS show at the McCormick Center September 10-15, 2018 and take a look at our new L-702/L-702SP Lathe Alignment Lasers.

- The L-702 will be a replacement for our L-700 Spindle Laser for mounting directly into a spindle of a lathe, turning center, rotary-dial machine or transfer-line machine to check the various spindle-axis alignments of these machines:

- Headstock spindle-axis parallelism to guideways, guideway flatness and straightness and headstock spindle-axis alignment to tailstock or subspindle.

- The L-702SP features a built-in scan plane that is perpendicular to the laser beam so that the squareness of cross-slides, turrets or other axes in multi-turn machines can be added to the above alignment checks.

Both lasers are compact and light weight and feature rechargeable lithium ion batteries and are compatible with our T-261A Simultaneous 4-Axis Target and A-1519-2.4ZB Wireless Scan Targets for extremely fast alignment checks and realignments using our real-time data update feature.

- The L-702 will be a replacement for our L-700 Spindle Laser for mounting directly into a spindle of a lathe, turning center, rotary-dial machine or transfer-line machine to check the various spindle-axis alignments of these machines:

- Hamar Laser Introduces Next-Generation L-702/L-702SP Spindle Alignment Lasers

September 5, 2018

Compact and versatile new L-702 and L-702SP Spindle Alignment Lasers help manufacturing plants cut costs and boost productivity

- The L-702 Spindle Alignment Laser is a straight-line laser for spindle alignments in lathes, turning centers, OD grinders, slant-bed lathes and transfer-line and rotary-dial machines.

- The L-702SP Spindle Alignment Laser with Scan Plane adds a perpendicular scan plane to the L-702 spindle laser beam for checking cross-slide, turret axis squareness and other milling axes in multi-axis, mill-turn machines.

- END OF LIFE ANNOUNCEMENT FOR S-1380B READ8 VERSION 3.XX

July 20, 2018

Hamar Laser Instruments, Inc. announces End of Life for Read8 version 3.61 software. This announcement marks the final milestone of the lifecycle management phase of the 3.X release family.

The tables below explain the Read8 life cycle management milestones as well as important information regarding dates and support options during this period.

Table 1. Milestone and Date for version 3 of the Read8 Software

Milestone Definition Date End of Life date (EOL) The EOL milestone signals the point at which phone support is no longer available for a particular software release family. At this time, the software will be removed from the corresponding download site(s) and will no longer be actively supported. Product information will be limited to the historical material available on Hamarlaser.com or other online resources and is subject to removal at a future date. July 20, 2018 Products Affected

The product numbers affected by this announcement and their replacements are listed in Table 2 (below). The software versions listed in the Product Replacement / Alternatives column represent the migration path for this discontinued software release family.

Table 2. Product part numbers affected by this announcement

Product Description Software Versions Affected Product Replacement / Alternatives S-1380/S-1380B 3.47, 3.61 S-1403 – Bore9 is a replacement for the Bore Module in Read8 S-1404 – Lathe9 is a replacement for the Spindle Mode in Read8 for lathe applications

S-1401 – Read11 is a replacement for the multiple scan target mode in Read8

For More Information

For more information about any of the replacement software please contact our Sales Department. Sales@hamarlaser.com

- M-124-LiPO Rechargeable 9V Battery Pack

June 15, 2018

An alternative power source for most of our scanning and straight-line lasers

- R-1356-2.4ZB with New Read15 Software – DISCONTINUED

April 25, 2018

Hand-held convenience, wireless communication via the ZigBee® Networking protocol, and multi- purpose Read15 alignment software

- New Video: L-700 4-Axis Lathe Alignment System – Capabilities and Specs

September 20, 2017

This video shows the L-700 4-Axis Lathe Alignment System’s features and capabilities. The L-700 can be used for lathes, turning centers, turret lathes, OD grinders, rotary-dial machines and transfer line spindle alignments to align headstock spindles to the main bed, saddle bed and also check tailstocks or subspindles. The L-700 offers a real-time, 4-axis measurement system with our Windows-based Lathe9 software that guides the user through the alignment checks on a lathe. It is very simple to operate, highly accurate and 2-3 times faster than traditional methods

- New 5-Part L-743 Floor Mill Video Series

June 30, 2016

Click here to access the full 5-part video series on Hamar Laser’s YouTube Channel.

A 5-part video series showing how to use the L-743 Triple Scan® Laser Alignment system on a 6-axis horizontal floor mill. Part 1 discusses the L-743 capabilities, specs and system components. Part 2 shows how to set up the L-743 on the horizontal mill. Part 3 shows how to take data for all the main axes. Part 4 shows how to take data on the rotary and other sub axes. Part 5 shows how to take flatness data on the main table and how to measure the sub table for parallelism.

- End of Support Announcement A-1532/A-1533 Single Axis Targets.

February 23, 2016

Effective February 23, 2016, Hamar Laser will no longer support the A-1532 and A-1533 Single Axis Targets. The replacement target is the A-1519-2.4ZB Single-Axis Wireless Target and R-1308 Single-Axis Readout. Please note, the R-1308 can be replaced with the R-1355-2.4ZB PDA Readout (displays the data for up to 10 A-1519-2.4ZB targets) or R-1307W-2.4ZB Readout (displays the data for up to 2 A-1519-2.4ZB targets).

End-of-Life Product Replacement Part Numbers 1. A-1532/A-1533 Single Axis Targets A-1519-2.4ZB Single-Axis Wireless Target and R-1308 Single-Axis Readout Please contact sales@hamarlaser.com or support@hamarlaser.com for pricing and answers to any questions you may have.

- L-700 Lathe Alignment System

- L-702SP 5-Axis Machine Tool & Spindle Alignment System

- L-703 Bore, Spindle & Straightness Laser Alignment Systems

- L-705 Bore Alignment Laser System

- L-706 Bore Laser System

- L-706 Small-Bore Alignment Laser System

- L-708 Internal Bore Laser Systems

- L-730 Precision Leveling Laser

- L-732 Precision Dual Scan® Laser